Machining Centers

Hi-M G1 PRO

Vertical Machining Center for Graphite

Hi-M G1 delivers high-speed, high-precision machining for dry cutting of graphite electrodes used in aluminum die casting process. It delivers quality machining by applying the highly dustproof and waterproof spindle and the optimum dust reduction system.

This system blocks the dust scattering and entry of fine dust created during the machining process. Hi-M G1 is easy to use due to its various add-on functions and enhanced user convenience.

Main features

Spindle with Built-in Motor

A high-power motor is integrated into the spindle shaft without any parts that transfer power between the motor and spindle. It minimizes vibration, noise, and power loss during high-speed rotations, increasing machining efficiency. The bearing grease lubrication system and synchronous temperature control minimize the influence of external temperature variation and improve smoothness.

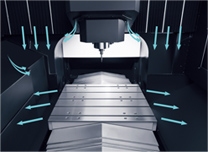

Dust proof (Air curtain system)

Air curtain system blocks the entry of fine dust into the feed system. (Air volume: 2 bar)

Dust collector

Sealed roof design collects dust generated from dry processing and prevents contamination due to fine dust. The door design that makes it easy to clean and discharge slideway lubricant maximizes user convenience.cement.

Tool Length Compensator

Tool length and diameter are measured and compensated automatically during the operation, minimizing non-cutting time and allowing any operator to reproduce high-precision results regardless of their work proficiency. Also, it detects any faults in the tools and prevents accidents before they happen.

Specifications

|

Item |

Unit |

Hi-M G1 |

|

Stroke (X / Y / Z) |

mm |

750 / 600 / 350 |

|

Rapid Speed (X / Y / Z) |

m/min |

25 / 25 / 20 |

|

Table Size (W x L) |

mm |

750 x 620 |

|

Table Loading Capacity |

kgf |

400 |

|

Max. Spindle Speed |

rpm |

24,000 |

|

Spindle Motor |

kW |

16 |

|

Type of Tool Shank |

- |

HSK-E40 (Opt: BT-30) |

|

Tool Storage Capacity |

ea |

24 |

|

Floor Space (Length x Width) |

mm |

2,165 x 2,575 |

|

Weight |

kgf |

4,800 |

|

NC Controller |

Siemens-828 (Opt: Fanuc 0i Plus) |

|