Machining Centers

Hi-M G2+

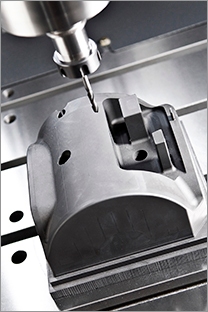

Vertical Machining Center for Graphite

Hi-M G2+ delivers high-speed, high-precision machining for dry cutting of graphite electrodes used in aluminum die casting process. It delivers quality machining by applying the highly dustproof and waterproof spindle and the optimum dust reduction system.

This system blocks the dust scattering and entry of fine dust created during the machining process. Hi-M G2+ is easy to use due to its various add-on functions and enhanced user convenience.

Main features

Dry process graphite machining

Optimal application for graphite

Optimal design for dust collect

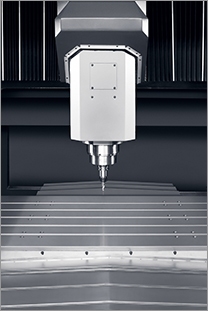

Compact machine design

Compact machine size

Simple and High rigid design structure

Small size & high performance dust collector

Excellent dust

collector

Sealed roof design for dust collector

Convenient door design for cleaning

High speed & high precision machining process

Optimal design structure by 3D / FEM Analysis

Wide LM guide for 3 axis(X/Y/Z)

Spindle coolant system

Specifications

|

Item |

Unit |

Hi-M G2+ |

|

Stroke (X / Y / Z) |

mm |

1,200 / 800 / 500 |

|

Rapid Speed (X / Y / Z) |

m/min |

25 / 25 / 20 |

|

Table Size (W x L) |

mm |

1,300 x 800 |

|

Table Loading Capacity |

kgf |

800 |

|

Max. Spindle Speed |

rpm |

20,000 |

|

Spindle Motor |

kW |

20 |

|

Type of Tool Shank |

- |

BT-40 |

|

Tool Storage Capacity |

ea |

16 (Opt: 24, 32) |

|

Floor Space (Length x Width) |

mm |

2,830 x 3,080 (Opt: 2,830 x 3,130) |

|

Weight |

kgf |

9,500 |

|

NC Controller |

Siemens-828 (Opt: Fanuc 0i Plus) |

|