Machining Centers

SIRIUS-1250

Hwacheon's extra-size bridge type vertical machining centers guarantee to enhance the quality of your large mold applications, such as large display frame, automotive and aerospace parts.

The SIRIUS series of large size vertical machining centers use powerful built-in motor spindles and high-speed, high precision milling heads complemented by Hwacheon's proprietary Oil-Jet cooling system-to guarantee consistent strong roughing performance and provide high quality product result hours after hours of high speed machining. Each SIRIUS vertical center is designed using 3D simulation FEM analysis to achieve structural rigidity which can translate to quality product results; while the Hwacheon designed machining software components enhance safety and work efficiency in your factory. The machines are configurable with many different options so that they can integrate perfectly to your work environment and application.

Main features

High-Rigidity Mechanical Structure

The bilateral gate structure in SIRIUS-1250 is the ideal design for distributing the vibration, the weight, and the heat throughout the entire frame. The machine is built through the finite element analysis to minimize the frame distortion which may be caused by machining condition or environment. The box way design for all axes is perfect for vibration absorption during heavy duty machining, and the Hwacheon-developed air levitation system on the X and Y axes keeps the workpiece stable while cutting a heavy-load subject. The distance between the spindle and the body is designed short, so the machine stays stable after a prolonged operation.

Highly rigid spindle design

The spindle integrates the motor to limit vibration, noise, and power loss at high speed rotation. The jet of oil is injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for possible thermal displacement and makes necessary adjustment in real time.

High-precision feed drive

The feed surface is coated with fluorinated resin, and is hand-scraped to precision by Hwacheon master technicians to minimize the friction. The servo motor is coupled directly to the drive; and the ball screws are tensile preloaded, so that the heat generated from the ball screws do not cause the distortion and affect the machining precision.

Specifications

|

Item |

Unit |

SIRIUS-1250 |

|

Stroke (X / Y / Z) |

mm |

2,500 / 1,250 / 750 |

|

Rapid Speed (X / Y / Z) |

m/min |

16 / 16 / 16 |

|

Table Size (W x L) |

mm |

2,800 x 1,250 |

|

Table Loading Capacity |

kgf |

5,000 |

|

Max. Spindle Speed |

rpm |

8,000 (Opt : 12,000) |

|

Spindle Motor |

kW |

30/25 |

|

Type of Tool Shank |

- |

BBT-50 |

|

Tool Storage Capacity |

ea |

40 |

|

Floor Space (Length x Width) |

mm |

7,305 x 4,145 |

|

Weight |

kgf |

25,500 |

|

NC Controller |

Fanuc 0i Plus |

|

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.

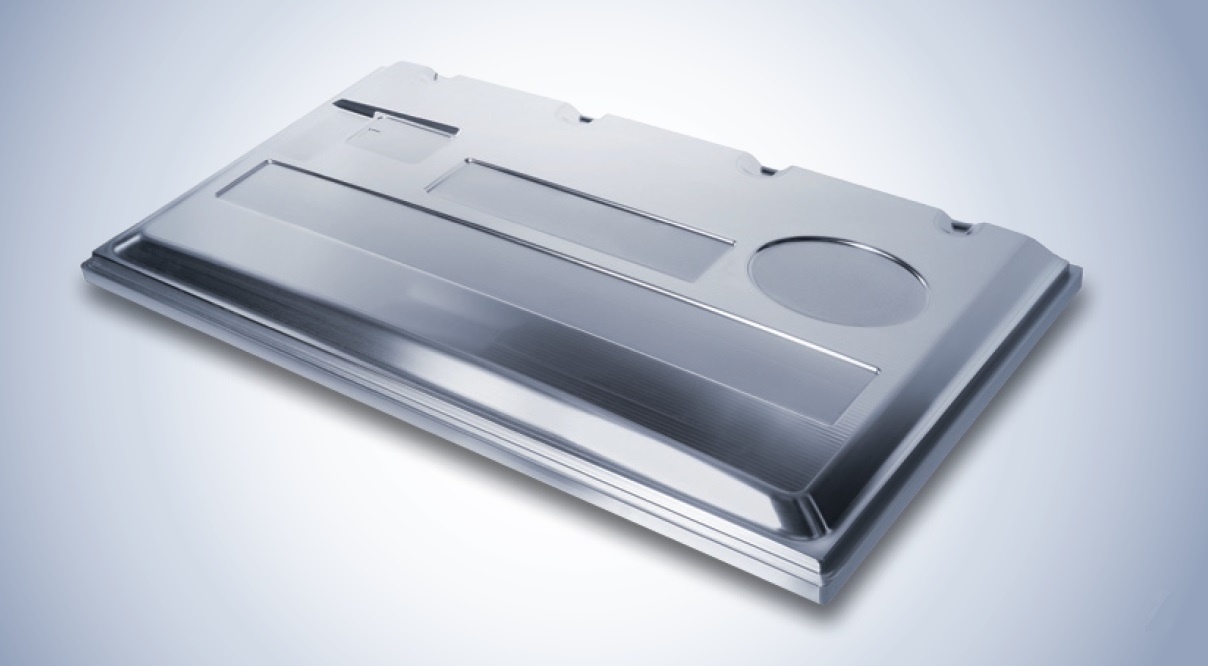

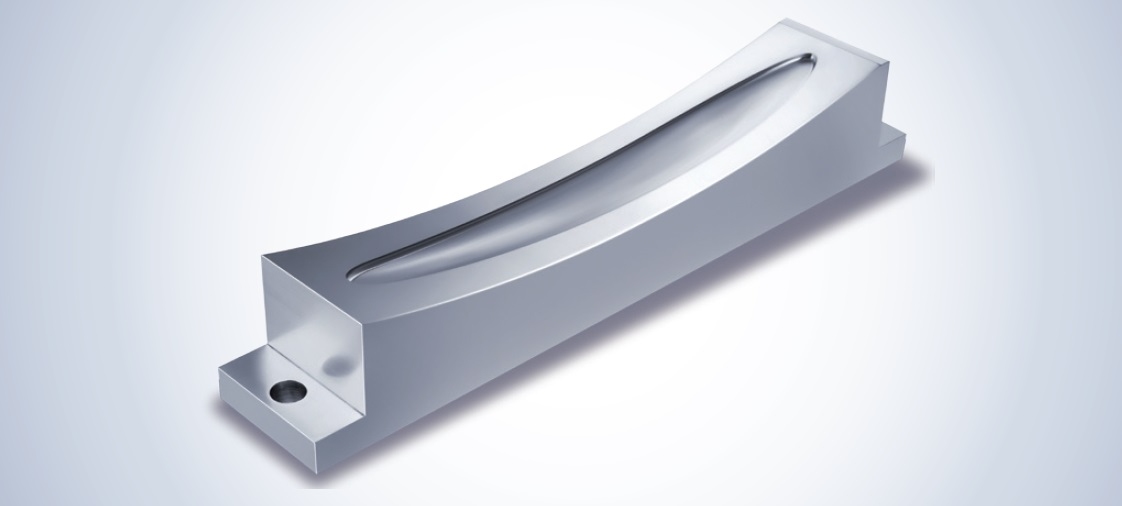

Process Sample

Auto Mobile Top Cover / Auto Driving / GC-250

63” LCD TV Back Cover / Home Appliances / KP4M

Auto Mobile Bumper Part / Auto Driving / KP4M

Auto Mobile Back Door Cover / Auto Driving / KP4M