Machining Centers

SIRIUS-UZ

SIRIUS-UZ occupies the peak position among the high-precision vertical machining center SIRIUS-U series that boast the world best performance.

SIRIUS-UZ provides the best machining solution in terms of product quality with its powerful roughing and precise finishing capabilities

Main features

High-Performance Spindle

Enhanced roughing capability compared to other machines of the same class

Uniform head rigidity regardless of Z-axis position

High-speed spindle that lengthens the lifespan of small tools and enhances machining conditions : 24,000 rpm (Opt.)

Convenient Usability

Reliable chip disposal

Built-in magnetic table with excellent usability for material installation (Opt.)

Product Quality Improvement

Optimized structure for precision machining

Control of thermal frame deformation due to internal chip/cutting oil

Decreased sensitivity to external temperature change

Separation of vibration sources

Specifications

|

Item |

Unit |

SIRIUS-UZ |

|||

|

Stroke (X / Y / Z) |

mm |

1,050 / 600 / 350 |

|||

|

Rapid Speed (X / Y / Z) |

m/min |

30 / 30 / 30 |

|||

|

Table size (W x L) |

mm |

1,200 x 600 |

|||

|

Table Loading Capacity |

kgf |

800 (Opt : 700 – Magnetic Table) |

|||

|

Max. Spindle Speed |

rpm |

20,000 (STD) |

12,000 |

14,000 |

24,000 |

|

Spindle Motor |

kW |

37 / 18.5 |

37 / 22 |

37 / 18.5 |

|

|

Type of Tool Shank |

- |

BBT-40 |

HSK-A63 |

||

|

Tool Storage Capacity |

ea |

30 (Opt : 40) |

|||

|

Floor Space (Length x Width) |

mm |

3,537 x 2,742 |

|||

|

Weight |

kgf |

11,500 |

|||

|

NC Controller |

Fanuc 31i |

||||

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.

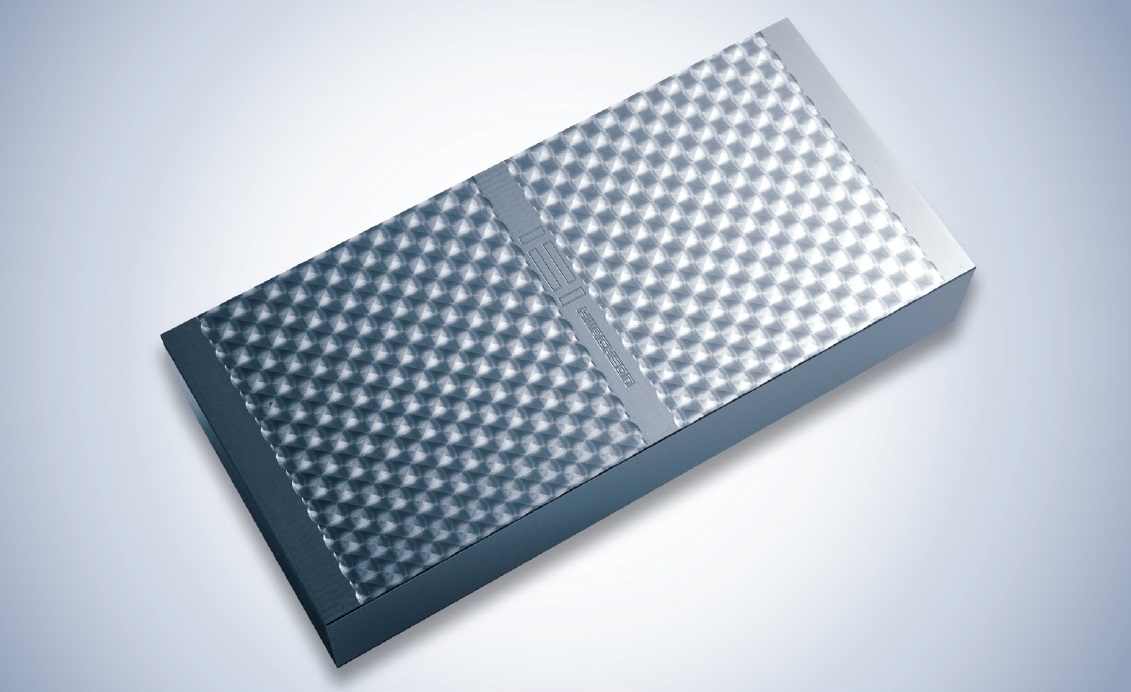

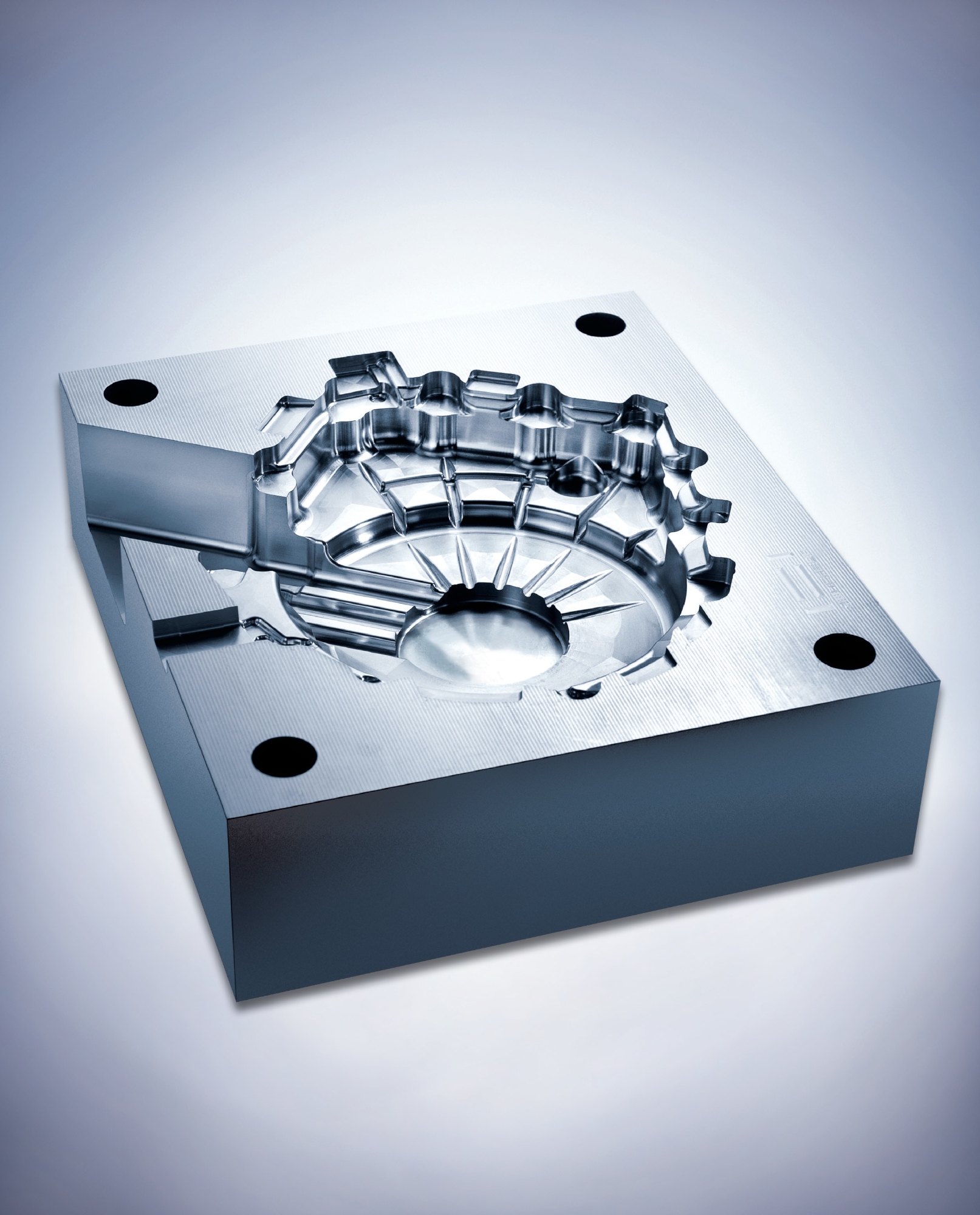

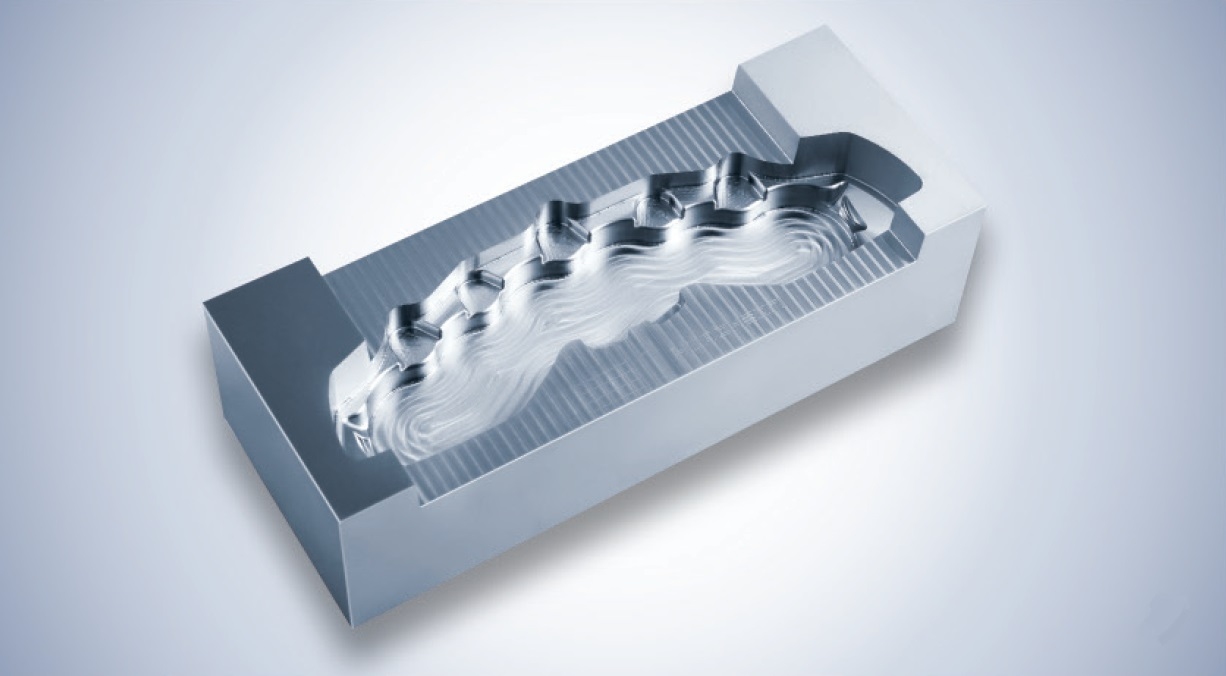

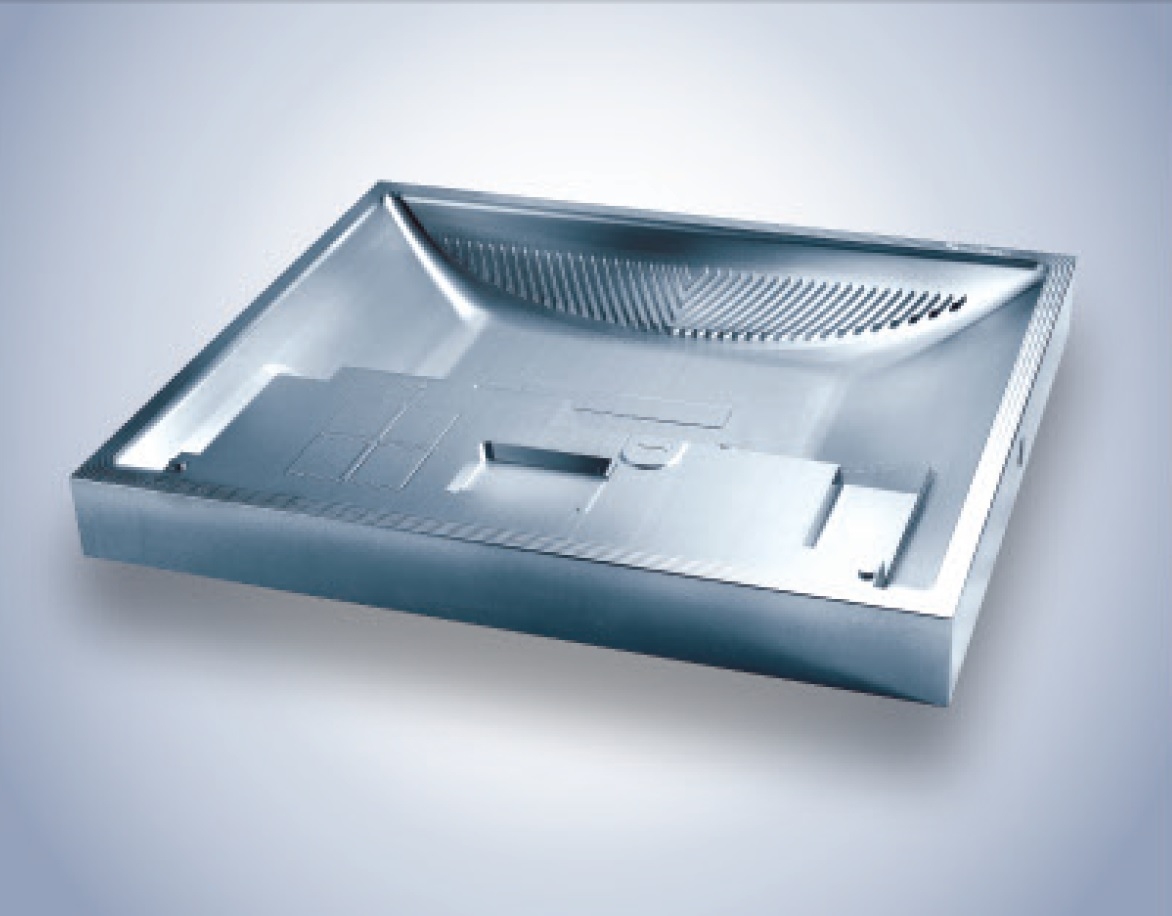

Process Sample

Die Casting / Automobile / SKD61(HRC 60)

Motor Bike / Sample / NAK80

Break Calliper / Automobile / NAK80

LCD Back Cover(Cavity) / Home appliances / NAK80