Machining Centers

VESTA-1050B

In heavy duty cutting, stability is the key

Everything about VESTA-850B/1050B is detail. These machining centers don't miss even the smallest detail to ensure top performance. The spindle is the heart of a machining center, and Hwacheon's technical know-how for the spindle is unrivaled. Hwacheon's high-performance spindle is designed using 3D simulations and FEM analysis, The motor is directly integrated into the spindle for stable, high speed cutting. To minimize thermal displacement and to increase the life of the spindle assembly, the unit is grease-lubricated and jacket cooled. The advanced feed drive complements the spindle for highly precise machining results every time. In heavy duty cutting, stability is the key

Main features

Tough machine structure

The super rigid C-type machine structure, designed with the help from finite element analysis, minimizes any distortion which may occur from changes in machining environment and condition The box way design for all axes is perfect for vibration absorption during heavy duty machining,

High-performance spindle

The spindle's automatic two-speed transmission switches gears to generate extra torque at low rpm machining, excellent for working on those hard-to-cut workpieces. The spindle is grease-lubricated and jacket cooled to minimize the thermal displacement and to increase the life of the spindle assembly.

High-precision feed drive

The feed surface is coated with fluorinated resin, and is hand-scraped to precision by Hwacheon master technicians to minimize the friction. To limit the distortion during the feed, 4-guide box way has been incorporated in the Y-axis, making the total width of the slide way wide to increase the bearing capacity and to decrease the surface area of friction. This optimizes the compressive force of the slide way, which translates to increased feed precision.

Specifications

|

Item |

Unit |

VESTA-1050B |

|

Stroke (X / Y / Z) |

mm |

1,050 / 600 / 600 |

|

Rapid Speed (X / Y / Z) |

m/min |

24 / 24 / 18 |

|

Table Size (W x L) |

mm |

1,150 x 600 |

|

Table Loading Capacity |

kgf |

1,000 |

|

Max. Spindle Speed |

rpm |

8,000 (Opt: 6,000) |

|

Spindle Motor |

kW |

18.5 / 15 |

|

Type of Tool Shank |

- |

BT-40 (Opt: BT-50) |

|

Tool Storage Capacity |

ea |

24 |

|

Floor Space (Length x Width) |

mm |

4220 x 2,247 |

|

Weight |

kgf |

6,970 (Opt: 8,000) |

|

NC Controller |

Fanuc 0i Plus |

|

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.

Process Sample

Front Knuckle / Automobile / FCD-450

Carrier / Automobile / FCD-450

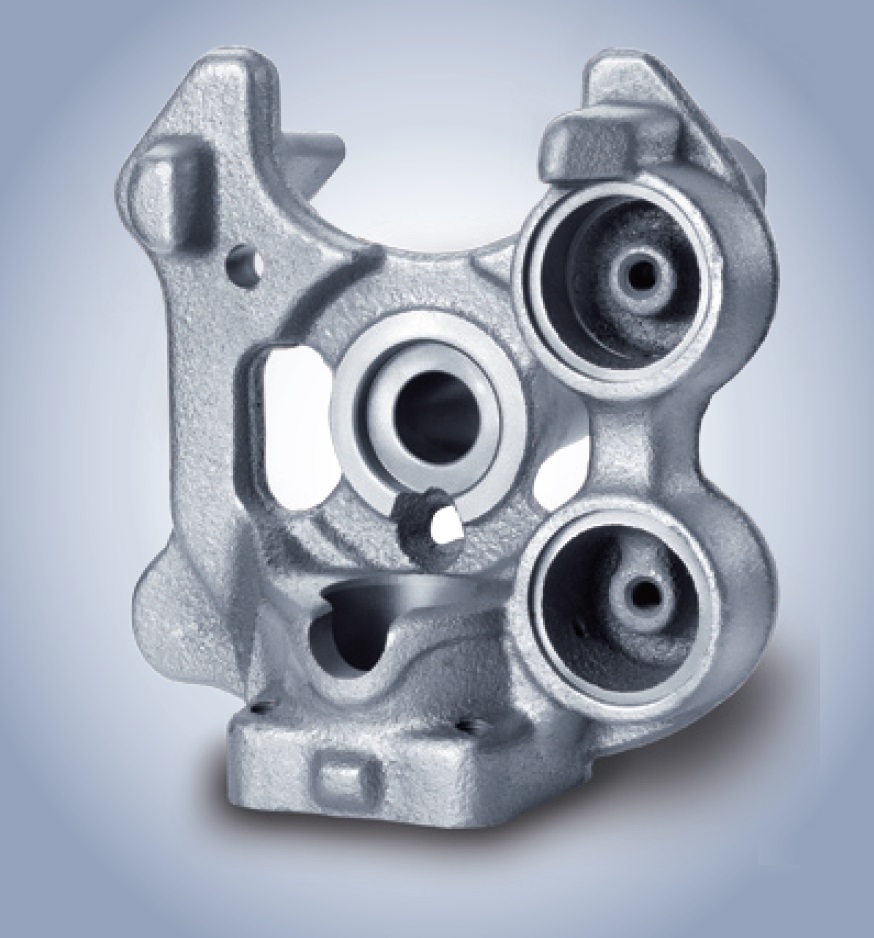

Valve Body / Plant Industry-Flow control Valve / CF-8M

Pump Housing / Plant Industry / GC-250