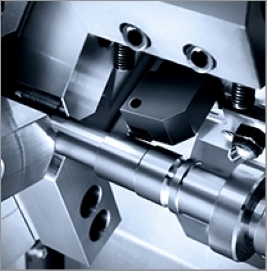

Turning Centers

Hi-TECH 200

VARIETY SPECIFICATIONS FOR CUSTOMER NEEDS

Customize Hi-TECH 200 with many different spindle sizes to fit your work.

Its small footprint and rigid box way structure will deliver quality and precisionafter hours and hours of non-stop operation.

Main features

Integrated, ultra-durable bed

Hi-TECH 200 has an integrated bed frame to minimize heat distortion, and the precision-polished wide guide surface and the ultra-durable bed absorb the vibration sufficiently, to assure high degree of cutting precision. All guide surfaces are rectangular and incorporate tack guide to maintain rigidity and accuracy in prolonged operation.

The Spindles to fit your application

Choose the right spindle per your workpiece and application.

Hi-TECH 200A Bar size : Ø51(2”) Chuck : 8”

Hi-TECH 200B Bar size : Ø64 (2.5”) Chuck : 10”

Hi-TECH 200C Bar size : Ø76 (3”) Chuck : 10”

C-axis unit

The C-axis allows for milling operation after turning. It's a separate high-performance gearbox unit with a servo motor, and the unit has the minimum feed increment of 0.001 degree, and the rapid feedrate of 45 rpm.

Quick indexing turret

Servo-type turret Number of tool stations: 12 (10 for 200C) Tool size: □ 25 ×Ø40 Turret indexing time (1 face): 0.15 secs Turret clamping force: 4,300 kgf

Specifications

|

Item |

Unit |

Hi-TECH |

Hi-TECH |

Hi-TECH |

Hi-TECH |

Hi-TECH |

Hi-TECH |

|

Max Cutting Diameter |

mm |

Ø350 |

Ø325 |

Ø350 |

Ø325 |

Ø350 |

Ø325 |

|

Max Cutting Length |

mm |

401.5 [631.5] |

318.5 [548.5] |

385 [615] |

302 [532] |

381 [611] |

298 [528] |

|

Travel (X / Z) |

mm |

195 / 430 [195 / 660] |

|||||

|

Rapid Travel (X / Z) |

m/min |

30 / 30 |

|||||

|

Chuck Size |

inch |

8 |

10 |

||||

|

Max Spindle Speed |

rpm |

5,000 |

3,500 |

||||

|

Min Index Angle |

deg |

- |

0.001 |

- |

0.001 |

- |

0.001 |

|

Spindle Motor |

kW |

18.5 / 15 |

|||||

|

Number of Tool Station |

ea |

12 |

10 |

||||

|

Floor Space (Length x Width) |

mm |

2,645 x 1,675 [L: 2,875 x 1,675] |

|||||

|

Weight |

kgf |

4450 [L: 5,050] |

4,600 [L: 5,200] |

4,650 [L: 5,250] |

4,800 [L: 5,400] |

4,650 [L: 5,250] |

4,800 [L: 5,400] |

|

NC Controller |

Fanuc 0i Plus |

||||||