Turning Centers

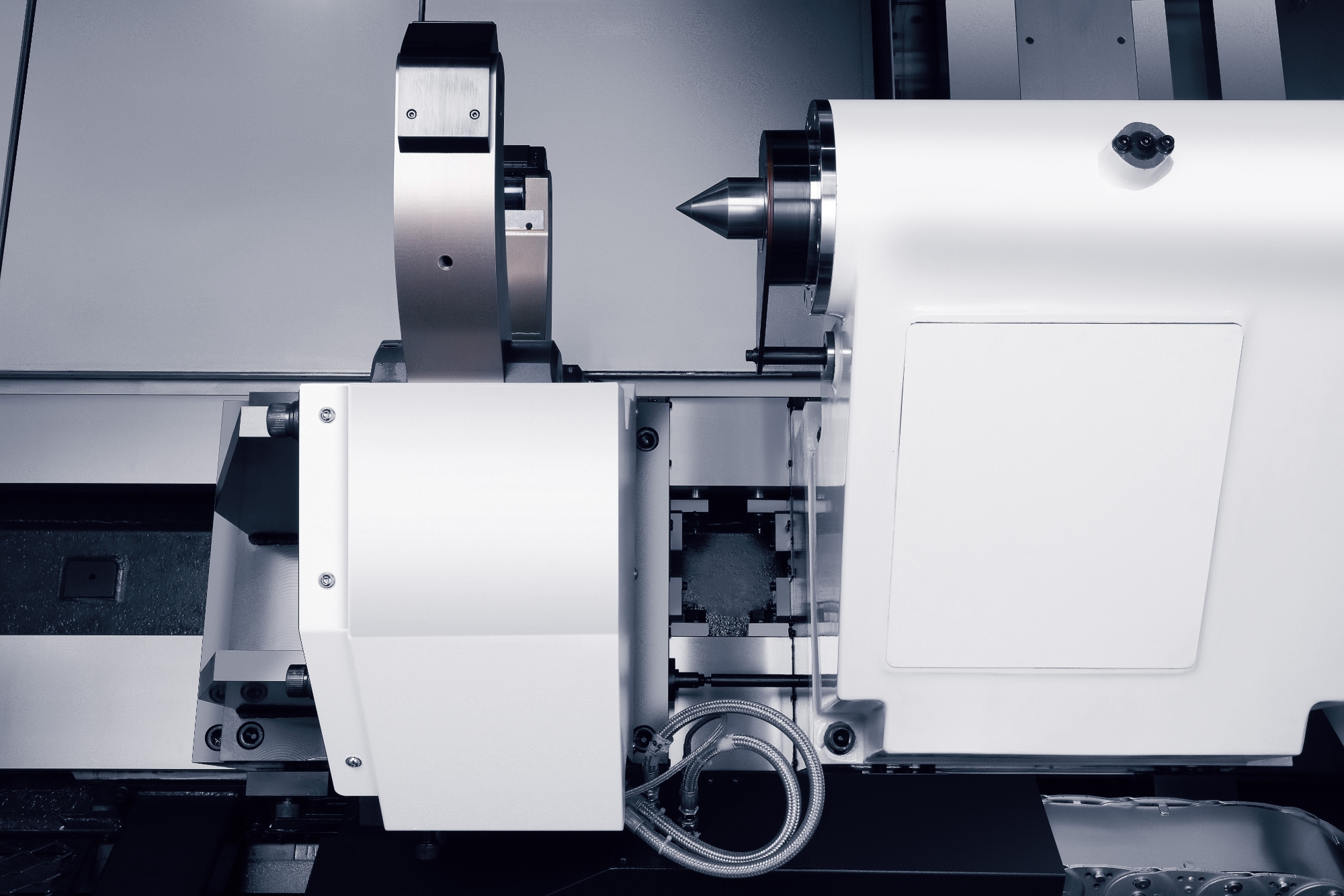

Hi-TECH 750

Outstanding machining performance with new design

Hi-TECH 750 adopts a bed structure suitable for strong cutting and box-way method on all guide surfaces to maintain rigidity and precision even in long-term use.

In addition, Hi-TECH 750 is capable of smooth cutting at the maximum machining diameter via the built-in gear drive system and greatly reduces the machining process time of large materials through combined machining using the Y-axis to increase productivity.

Main features

The Programmable Hydraulic Tailstock

The tail spindle is activated by foot switches or a program

User Friendly Design

15" display as standard (Non-touch Type Display) QWER Key MDI

Part Program Storage Length : 2MB

Number of Register Able Programs : Max 1,000ea

Enhanced operability by optimizing the layout and improving the touch feeling of control buttons.

Long time continuous DNC operation with the CF card even without the data server.

Specifications

|

Item |

Unit |

Hi-TECH 750A |

Hi-TECH 750A/MC |

Hi-TECH 750A/YMC |

Hi-TECH 750B |

Hi-TECH 750B/MC |

Hi-TECH 750B/YMC |

|

Max Cutting Diameter |

mm |

Ø 1,200 |

|||||

|

Max Cutting Length |

mm |

2,250 |

2,193 |

2,198 |

2,141 |

||

|

Travel (X / Z) |

mm |

430 / 2,350 (Opt: 3,350 / 4,350) |

|||||

|

Rapid Travel (X / Z) |

m/min |

18 / 18 (Opt: 14 / 10) |

|||||

|

Chuck Size |

inch |

18 (Opt: 15, 21) |

21 (Opt: 24) |

||||

|

Max Spindle Speed |

rpm |

1,800 (Opt: 15” : 1,800 / 21” : 1,700) |

1,500 (Opt: 24 : 1,400) |

||||

|

Min. Index Angle |

deg |

- |

0.001 |

0.001 |

- |

0.001 |

0.001 |

|

Spindle Motor |

kW |

37 / 30 (Opt. 45 / 37) |

45 / 37 |

||||

|

Number of Tool Station |

ea |

12 |

|||||

|

Floor Space (Length x Width) |

mm |

6,435 (Opt: 7,435 / 8,435) x 3,060 |

|||||

|

Weight |

kgf |

20,500 (Opt: 23,500 / 27,000) |

21,000 (Opt: 24,000 / 27,500) |

22,000 (Opt: 25,000 / 28,500) |

20,800 (Opt: 23,800 / 27,300) |

21,300 (Opt: 24,300 / 27,800) |

22,300 (Opt: 25,300 / 28,800) |

|

NC Controller |

Fanuc 0i Plus |

||||||