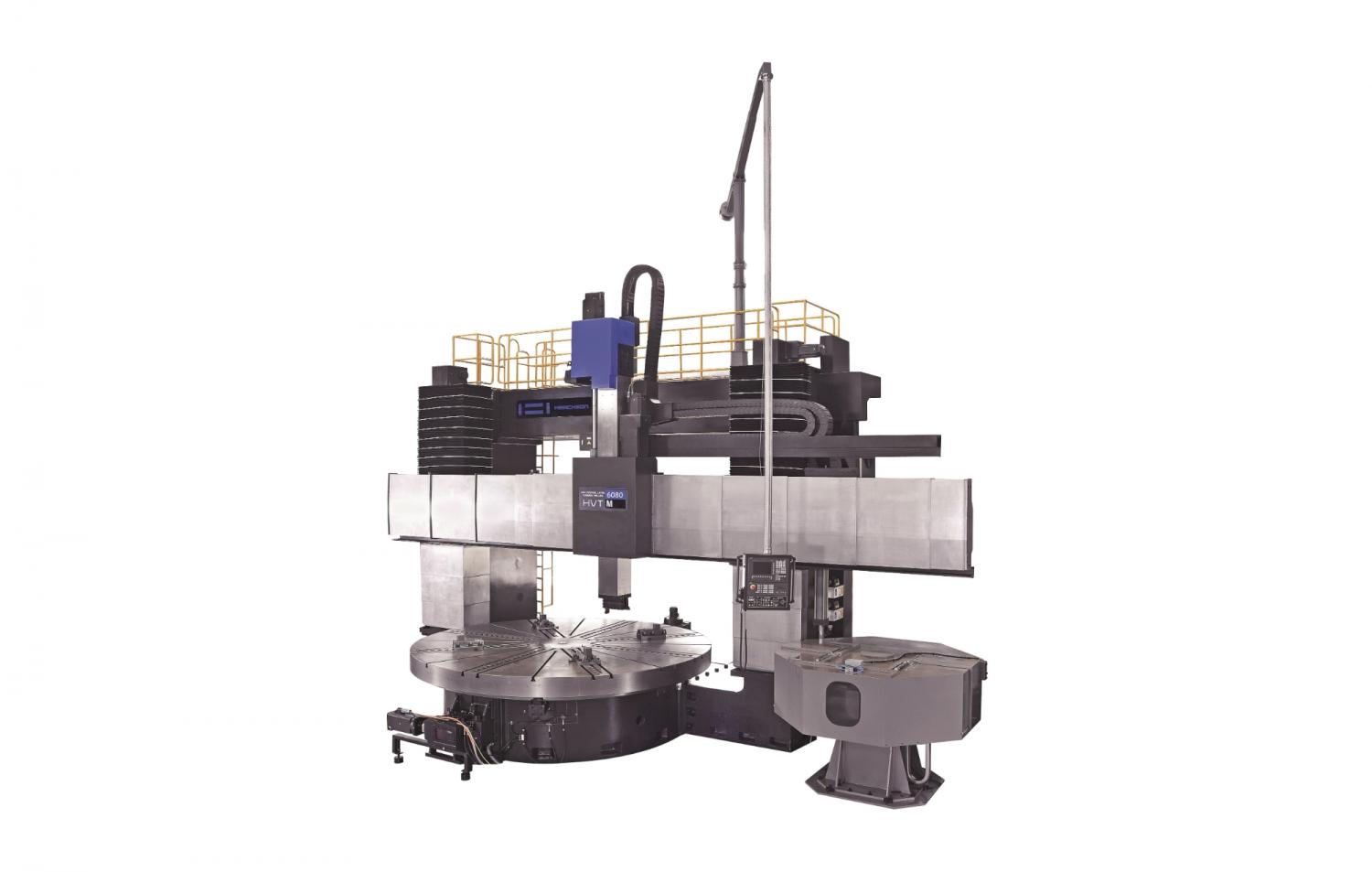

Turning Centers

VT-4500

VT-4500 is built on one piece basic bed to ensure best rigidity and to limit thermal displacement.

Its extra wide precision hand scraped and polished guide ways and the unique overall machine design provides exceptional vibration absorption and rigidity.

High rigid & low balancing all-in-one structure from head to base frame ensures stable machining. .

Milling equipment which is best performance in its class is driven by C-axis gear box & servo motor(5.5kW) and is possible for various process with only one-time chucking with precise indexing(0.001˚) contributing to perfect machining process such as milling, tapping and drilling.

Main features

High-Rigidity Frame Structure

Double column frame structure enables hard roughing, and the table and bed are manufactured from meehanite cast iron to limit deformation. The design has been optimized through 3D CAD and finite element analysis.

No-Contact, Long-Life Hydrostatic Bearing

Application of high-rigidity hydrostatic bearing produces higher quality machined surface than ordinary bearing due to vibration dampening by oil film and forced oil cooling system. No-contact bearing allows semi-permanent usage.

C-Axis for Turn Mill

The built-in C-axis control unit enables precise operations of boring, drilling, milling, and tapping, etc. to meet various machining conditions. (C-axis minimum table division degree: 0.0001)

Curvic Coupling

Curvic coupling of the tool holder and ram enables high-precision machining.

Specifications

|

Item |

Unit |

VT-4500 |

|

Swing over table |

mm |

Ø 5,000 |

|

Max. table loading capacity |

kgf |

40,000 |

|

Max Cutting Diameter |

mm |

Ø 5,000 |

|

Max Cutting Length |

mm |

2,500 |

|

Travel (X / Z / W) |

mm |

-250 ~ 4,100 / 1,500 / 2,000 |

|

Rapid Travel (X / Z / W) |

m/min |

|

|

Max Spindle Speed |

rpm |

1 ~ 50 |

|

Min. Index Angle |

deg |

0.001 |

|

Spindle Motor |

kW |

136 / 92 |

|

Number of Tool Station |

ea |

12 |

|

Floor Space (Length x Width) |

mm |

11,500 x 7,500 |

|

Weight |

kgf |

140,000 |

|

NC Controller |

Siemens-840 (Opt: Fanuc 31i) |

|