Machining Centers

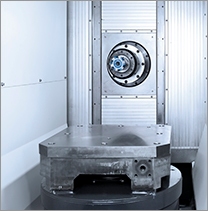

A 600

HORIZONTAL MACHINING CENTER FOR FLEXIBLE MANUFACTURING

A 600 is built with highly rigid box on box design for stable machining, and its small footprint is perfect for FA system. The spindle integrates the motor to limit vibration, noise, and power loss at high speed rotation. The jet of oil is injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat.

The servo motor's precision worm gear design increases the motor's torque, and the large-capacity oil-pressure brake system provides stable and accurate machining when performing fixed-angle roughing and boring.

Main features

B-axis drive

The servo motor's precision worm gear design increases the motor's torque, and the large-capacity oil-pressure brake system provides stable and accurate machining when performing fixed-angle roughing and boring.

High-precision feed drive

The roller linear guide feeds a heavy workpiece stably and smoothly; and the direct-coupled servo motor minimizes backlash during traverse. The machine automatically injects the lubricant onto the linear guide and the ball screws to maintain precision.

Specifications

|

Item |

Unit |

A 600 HSK-A63 |

A 600 BT-50 |

|

Stroke (X / Y / Z / W) |

mm |

600 / 600 / 800 / - |

560 / 580 / 800 / - |

|

Rapid Speed (X / Y / Z / W / B) |

m/min |

60 / 60 / 60 / - / 30 |

50 / 50 / 60 / - / 30 |

|

B-axis Rotation angle |

deg |

360 |

|

|

Min. Indexing Angle |

deg |

0.001 |

|

|

Table size (W x L) |

mm |

500 x 500 |

|

|

Table Loading Capacity |

kgf |

600 |

|

|

Max. Spindle Speed |

rpm |

16,000 (8,000) |

8,000 |

|

Spindle Motor |

kW |

22 / 18.5 |

|

|

Type of Tool Shank |

- |

HSK-A63 (Opt: BT-40) |

BT-50 (Opt: HSK-A100) |

|

Tool Storage Capacity |

ea |

40 (Opt: 60) |

40 |

|

Floor Space (Length x Width) |

mm |

6,353 x 1,824 - Plane Type 40T |

6,353 x 3,246 - Plane Type |

|

NC Controller |

Fanuc 0i Plus |

||