Turning Centers

CUTEX-240

The CUTEX-240 integrated turning center is built tough.

This compact turning center offers many different spindles for different jobs; the programmable tailstock and steady rest allow for turning extra long workpieces; and other optional features such as the sub spindle and the turnmill function make possible complex, multiple processes with a single chucking.

Plus, component add-ons such as the bar feeder and parts catcher will help your business get results even faster.

Main features

Integrated, ultra-durable bed

CUTEX-240 has an integrated 45-degree angle bed frame to minimize heat distortion, and the precision-polished wide guide surface and the unique bed design absorb the vibration sufficiently, to ensure high degree of precision at hard turning. All guide surfaces are rectangular and incorporate tack guide to maintain rigidity and accuracy in prolonged operation.

High-Rigidity Spindle

High-rigidity, high-precision recuperative cylindrical roller bearing of Ø240 mm (9.45”) and double thrust angular bearing are mounted on the front to maintain superb stability even during hard roughing operation. A powerful AC 45 kW spindle motor is coupled directly to 2 gearboxes, producing class-leading high torque at various rotations from low speed to high speed. (4-speed automatic transmission.

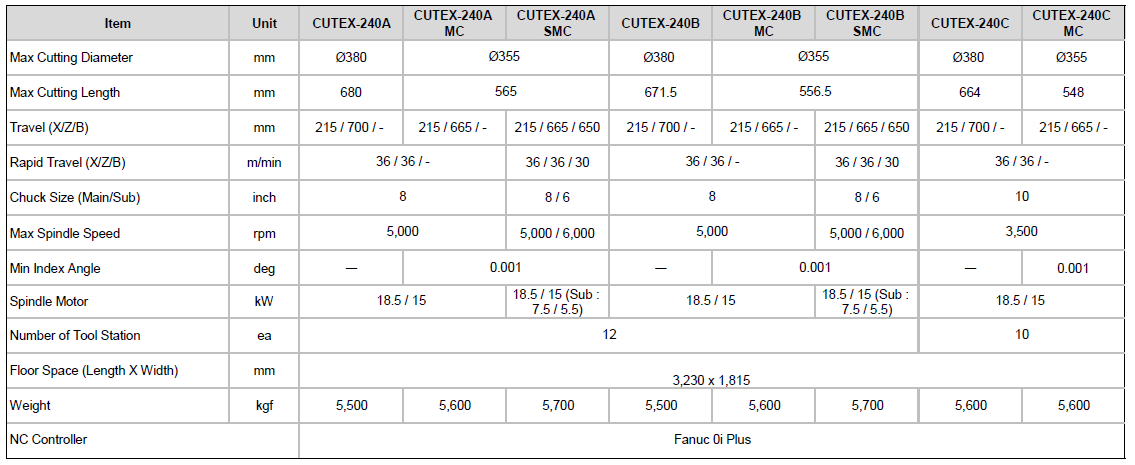

Specifications

Mounting software

Hwacheon Lathe Tool Load Detection System

The Hwacheon Lathe Tool Load Detect System constantly detects and diagnoses the toolload under a process to prevent tool wear and damage, and to keep your machine andtools in optimal shape.