Machining Centers

HiT-360D

Optimum Base Speed for Aluminum Machining

The direct spindle structure and BT-30 Tool shank are adopted as the standard and the ceramic bearing is implemented to minimize the thermal deformation. High-quality products are produced with stability even during prolonged machining. Enhanced user convenience and machining optimization through various add-on functions further boost the product quality.

Main features

High-Speed Spindle

The main BBT-30 spindle (two-face contact) prevents the Z-axis displacement and reduces vibrations during high-speed rotations, realizing high-speed, high-precision machining. Direct spindle connection offers minimum number of mini-taps and drilling to enable optimum base speed for IT/HDD/aluminum machining.

Stable Feed Structure

HiT- 360D uses low-noise, high-precision tubeless ball screw structure and deflector-type, compact ball screws to prevent rupturing of tubes during high-speed feeding. The servo motor is directly coupled to the axes for precise feeding.

Auto Pallet Changer

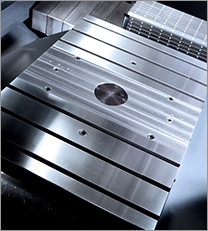

With the non lift-up rotation system, the table does not move up or down to rotate and instead the curvic coupling inside the APC moves up and down to maintain iterative precision. (Curvic coupling: It uses position control to maintain position & iterative precision.)

Specifications

|

Item |

Unit |

HiT-360D |

|

Stroke (X / Y / Z) |

mm |

520 / 360 / 300 |

|

Rapid Speed (X / Y / Z) |

m/min |

20 / 30 / 30 |

|

Table Size (W x L) |

mm |

2 - 650 x 400 |

|

Table Loading Capacity |

kgf |

250 |

|

Max. Spindle Speed |

rpm |

12,000 (Opt: 24,000) |

|

Spindle Motor |

kW |

7.5 / 5.5 |

|

Type of Tool Shank |

- |

BBT-30 |

|

Tool Storage Capacity |

ea |

21 |

|

Floor Space (Length x Width) |

mm |

2,977 x 1,884 |

|

Weight |

kgf |

3,500 |

|

NC Controller |

Fanuc 0i Plus (Opt: Siemens-828) |

|