Turning Centers

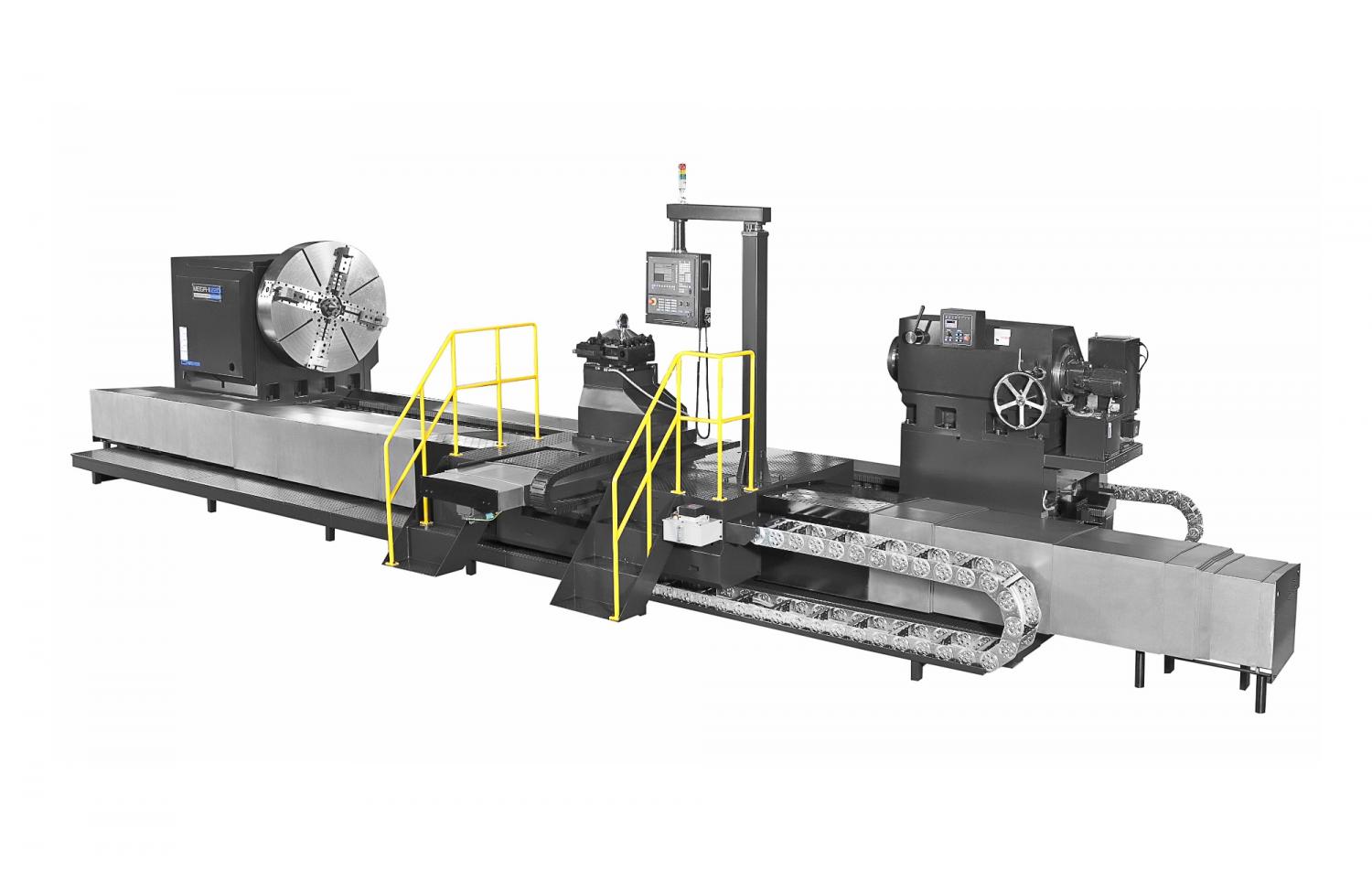

MEGA II 200

MEGA II Series is heavy duty large-sized horizontal CNC lathe.

MEGA II series are specifically designed for ship building, wind power, mining, new & renewable energy as well as large & heavy duty precision parts for aircraft industries.

Main features

Headstock with Thermal Displacement-Minimizing Rib Frame

The headstock provides stable support for the spindle with its high-precision cylindrical roller bearing, and the gearbox with gear and shaft specially treated with heat during grinding delivers excellent stability and precision. The oil, cooled by an external cooling system, automatically circulates to lubricate each drive and support sections to minimize thermal displacement caused by heat.

High-Rigidity Structure

The high-rigidity 3-way bed, capable of hard cutting, has been designed in separate units that can be connected easily, and the wide sliding surface bed with the maximum width of 1,200 mm enables high-load hard cutting. The bed has been designed to allow discharge of chips by vertically dropping them, and the chip conveyor is convenient to use.

Built-in Tailstock

The large tailstock with the built-in quill rotation structure is designed to have a rigid frame with the 3-point support system. Its rack-and-pinion steering, automatic feeding by an electrical motor, and a dual safety system for braking and sliding prevention allow the operator to work in safety and comfort. Implementation of the forced lubrication cooling system minimizes thermal displacement.

Z-Axis Ball Screw and Support

The nut rotation drive system with clamped ends minimizes vibrations during rapid feeding. A saddle with LM guide and anti-deflection ball screw support are mounted on the front of the bed to enable machining without drooping or vibrations.

Specifications

|

Item |

Unit |

MEGAII-200 |

||||

|

Swing Over Bed |

mm |

Ø 2,050 |

||||

|

Swing Over Cross Slide |

mm |

Ø 480 ~ Ø 1,600 |

||||

|

Max Cutting Length |

mm |

6,000 |

8,000 |

10,000 |

12,000 |

17,000 |

|

Travel (X / Z) |

mm |

900 / 6,300 |

900 / 8,300 |

900 / 10,300 |

900 / 12,300 |

900 / 17,300 |

|

Rapid Travel (X / Z) |

m/min |

4 / 6 |

||||

|

Chuck Size |

inch |

|

||||

|

Max Spindle Speed |

rpm |

1~130 |

||||

|

Spindle Motor |

kW |

137 / 92 |

||||

|

Number of Tool Station |

ea |

4 |

||||

|

Floor Space (Length x Width) |

mm |

13,500 x 4,200 |

15,500 x 4,200 |

17,500 x 4,200 |

19,500 x 4,200 |

24,500 x 4,200 |

|

Weight |

ton |

77 |

82 |

87 |

92 |

106 |

|

NC Controller |

Siemens-828 (Opt: Fanuc 0i) |

|||||