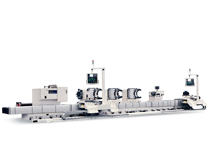

Horizontal

MEGA R100/15

HEAVY DUTY CNC ROLL LATHE.

MEGA R100/15 is specialized in machining the high precision rools supported with 4-way guide way system and designed for high precision cutting.

Main features

High-Rigidity Mechanical Structure

The saddle, designed to be safe and sturdy through finite element analysis, is fitted with gearbox guide way and has a highly rigid structure that enables roughing in stable conditions.

High-Precision Feed System (X- and Z-Axis)

The Z-axis gearbox is integrated into the saddle frame to be even sturdier, and the feed system has a rack-and-pinion structure and there is no limit on the workpiece length. The X-axis feed system is coupled directly to the precision ball screw that allows high-precision position control.

High-Rigidity Headstock

The headstock provides stable support for the spindle with its thermal displacement-minimizing rib frame and cylindrical roller bearing, and the gearbox with gear and shaft specially treated with heat during grinding delivers excellent stability and precision.

Large Tailstock

The large tailstock with the built-in quill rotation structure is designed to have a rigid frame with the 3-point support system. Its rack-and-pinion steering, automatic feeding by an electrical motor, and a dual safety system for braking and sliding prevention allow the operator to work in safety and comfort.

Specifications

|

Item |

Unit |

MEGA- R100 |

|||||

|

Swing Over Bed |

mm |

Ø 1,600 |

|||||

|

Swing Over Cross Slide |

mm |

Ø 1,000 |

|||||

|

Max Cutting Length |

mm |

3,000 |

4,000 |

5,000 |

6,000 |

8,000 |

10,000 |

|

Travel (X / Z) |

mm |

660 / 3,000 |

660 / 4,000 |

660 / 5,000 |

660 / 6,000 |

660 / 8,000 |

660 / 10,000 |

|

Rapid Travel (X / Z) |

m/min |

6 / 6 |

|||||

|

Chuck Size |

inch |

|

|||||

|

Max Spindle Speed |

rpm |

1 ~ 500 |

|||||

|

Spindle Motor |

kW |

114 / 71 |

|||||

|

Number of Tool Station |

ea |

4 |

|||||

|

Floor Space (Length x Width) |

mm |

8,725 x 3,325 |

9,725 x 3,325 |

10,725 x 3,325 |

11,725 x 3,325 |

13,725 x 3,325 |

15,725 x 3,325 |

|

Weight |

ton |

51 |

53 |

55 |

57 |

61 |

65 |

|

NC Controller |

SIEMENS-828 |

||||||