Machining Centers

SMART Ua STEEL

Smart Machine for Machining Small Steel Mold

Smart machine which realizes the automated machining solution for steel with a depth under 100mm

SMART Ua STEEL is a steel-machining smart machine which combines the self-developed smart software solution and the unique machining optimization control technology of Hwacheon.

Once you select a 3D model, this smart solution carries out CAM computation, machining path optimization, material measurement, and machining automatically. The smart solution allows you to integrate user’s knowledge in the actual machining process.

Main features

H-SMART S

SMART UaSTEEL’s dedicated HMI with an all-in-one solution for all processes from CAM computation to machining

Magnetic Table (Std.)

With table-integrated structure, there is no loss in Z-axis area

Cables are hidden inside the table to secure the safeand tidy machining area

Automatic Workpiece Changer (Opt.)

Improving productivity by minimizing non-machining time (workpieces can be mounted from the outside of the machine)

Unmanned operation using a pallet container

Specifications

|

Item |

Unit |

SMART Ua STEEL |

|||

|

Stroke (X / Y / Z) |

mm |

1,050 / 600 / 550 |

|||

|

Rapid Speed (X / Y / Z) |

m/min |

36 / 36 / 36 |

|||

|

Table size (W x L) |

mm |

1,200 x 600 |

|||

|

Table Loading Capacity |

kgf |

800 (Opt : 700 – Magnetic Table) |

|||

|

Max. Spindle Speed |

rpm |

20,000 (STD) |

12,000 |

14,000 |

24,000 |

|

Spindle Motor |

kW |

37 / 18.5 |

37 / 22 |

37 / 18.5 |

|

|

Type of Tool Shank |

- |

BBT-40 (Opt : HSK-A63) |

HSK-A63 |

||

|

Tool Storage Capacity |

ea |

120 |

|||

|

Floor Space (Length x Width) |

mm |

5,730 x 5,320 |

|||

|

Weight |

kgf |

20,000 |

|||

|

NC Controller |

H-SMART |

||||

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.

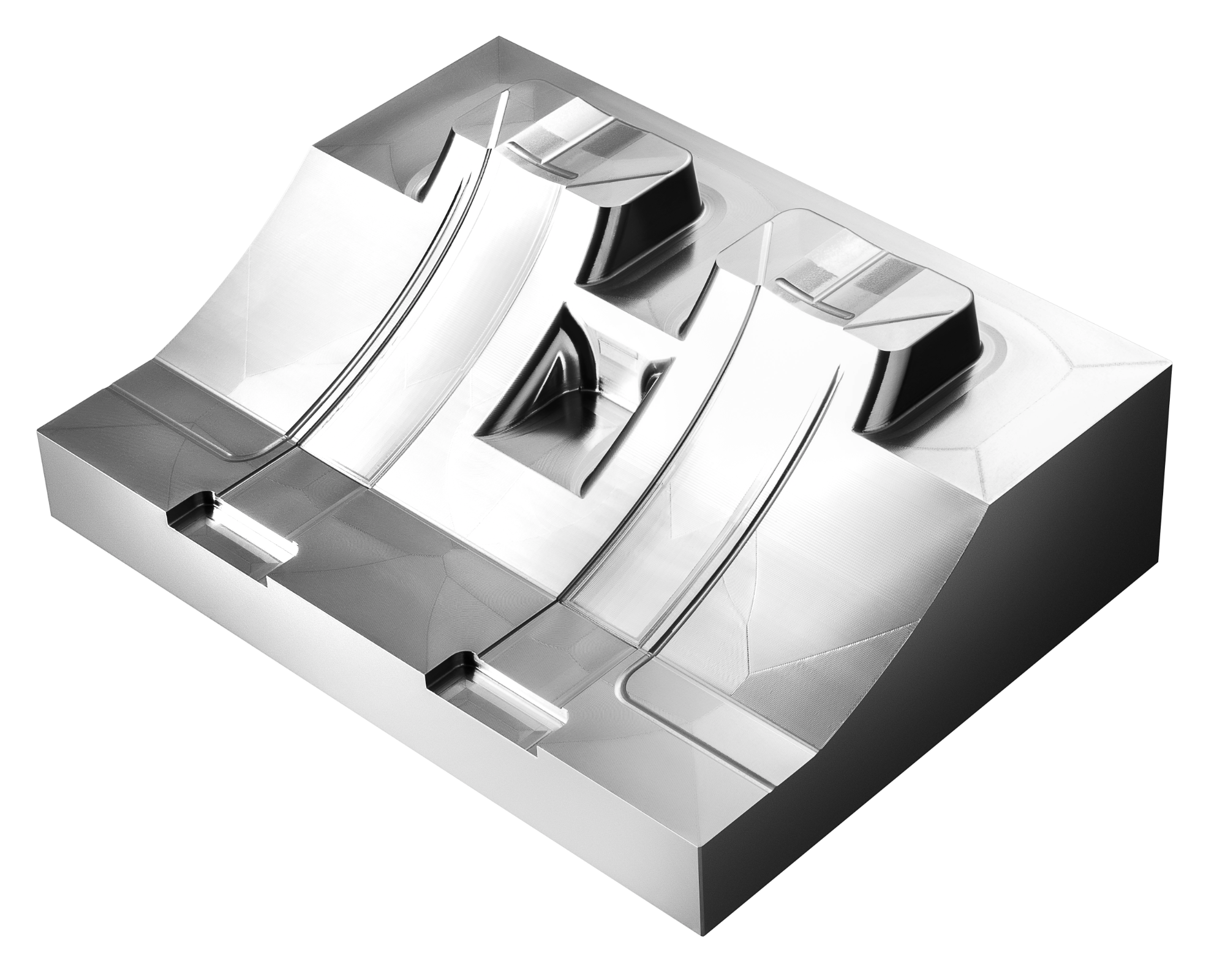

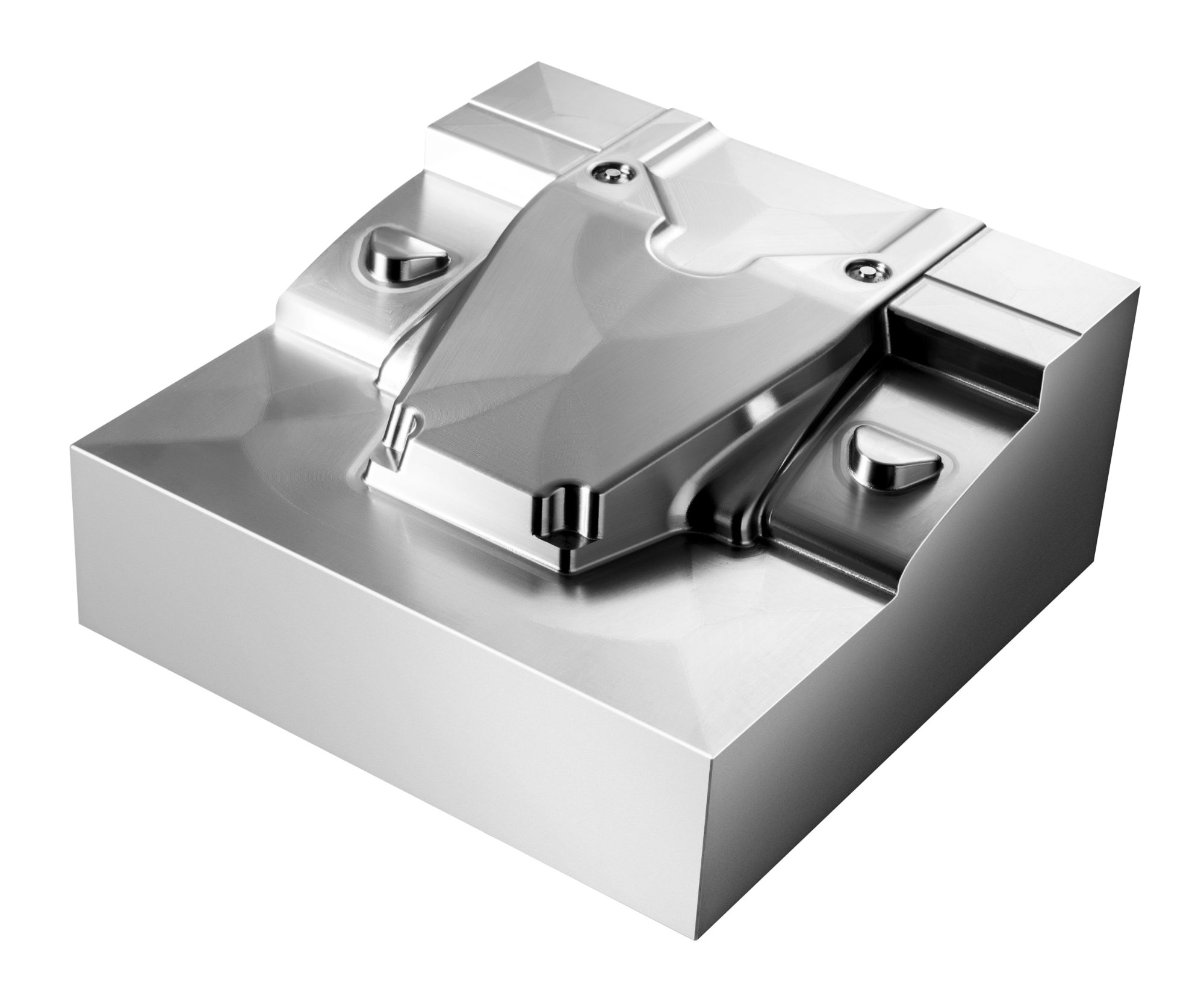

Process Sample

Core / Injection Mold / KP4M

Slide Core / Injection Mold / KP4M