Machining Centers

UH500

VERTICAL MACHINING CENTER FOR PRECISION DIE & MOLD

THIS IS THE PERFECT DIE & MOLD SOLUTION YOU'VE BEEN LOOKING FOR

UH500 is a vertical die & mold center whose performance is world leading. It provides your company with a total one stop production solution, form tools selection to final product.

Main features

The bilateral gate structure

The bilateral gate structure in UH500 is the ideal design for distributing the vibration, the weight, and the heat throughout the entire frame. The machine is built through the finite element analysis to minimize the frame distortion which may be caused by machining condition or environment. The distance between the spindle and the body is designed short, so the machine stays stable after a prolonged operation.

The spindle integrates the motor

The spindle integrates the motor to limit vibration, noise, and power loss at high speed rotation. The jet of oil is injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for possible thermal displacement and makes necessary adjustment in real time.

Easy Work Setup

Optimized for mold machining, the User Graphic Measuring Cycle offers a convenient programming environment and delivers precision machining by measuring the workpiece in the machine and comparing data.

Specifications

|

Item |

Unit |

UH500 |

|

Stroke (X / Y / Z) |

mm |

750 / 500 / 350 |

|

Rapid Speed (X / Y / Z) |

m/min |

24 / 24 / 24 |

|

Table Size (W x L) |

mm |

850 x 500 |

|

Table Loading Capacity |

kgf |

800 |

|

Max. Spindle Speed |

rpm |

20,000 (Opt : 32,000) |

|

Spindle Motor |

kW |

24 (Opt : 20) |

|

Type of Tool Shank |

- |

BT-40 (Opt: HSK-A63, HSK-E40) |

|

Tool Storage Capacity |

ea |

24 |

|

Floor Space (Length x Width) |

mm |

2,377 x 3,579 |

|

Weight |

kgf |

8,000 |

|

NC Controller |

H-SMART |

|

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.

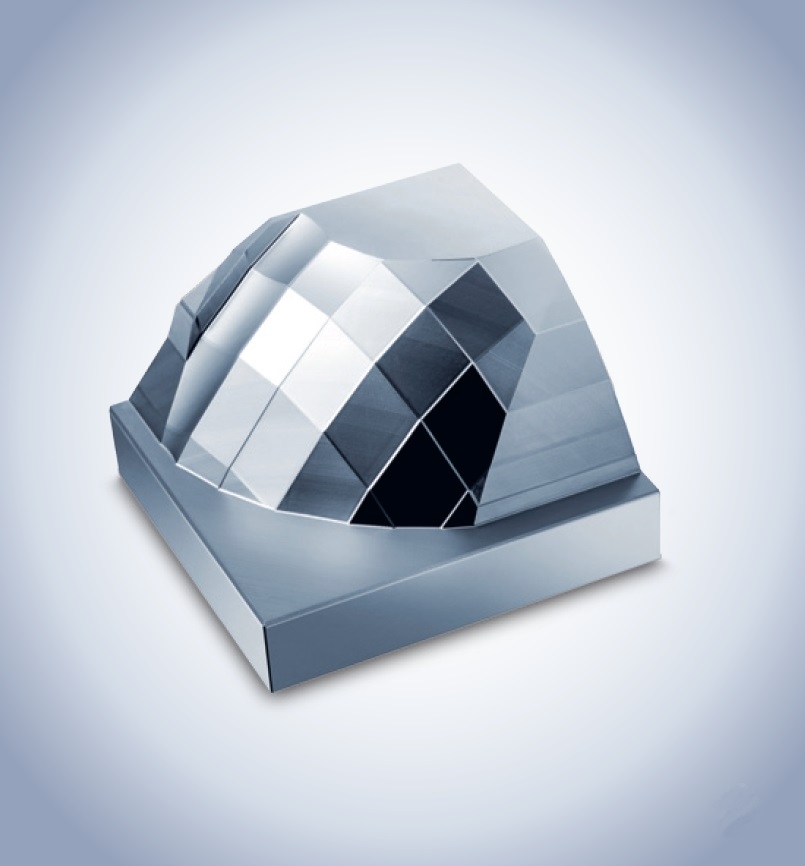

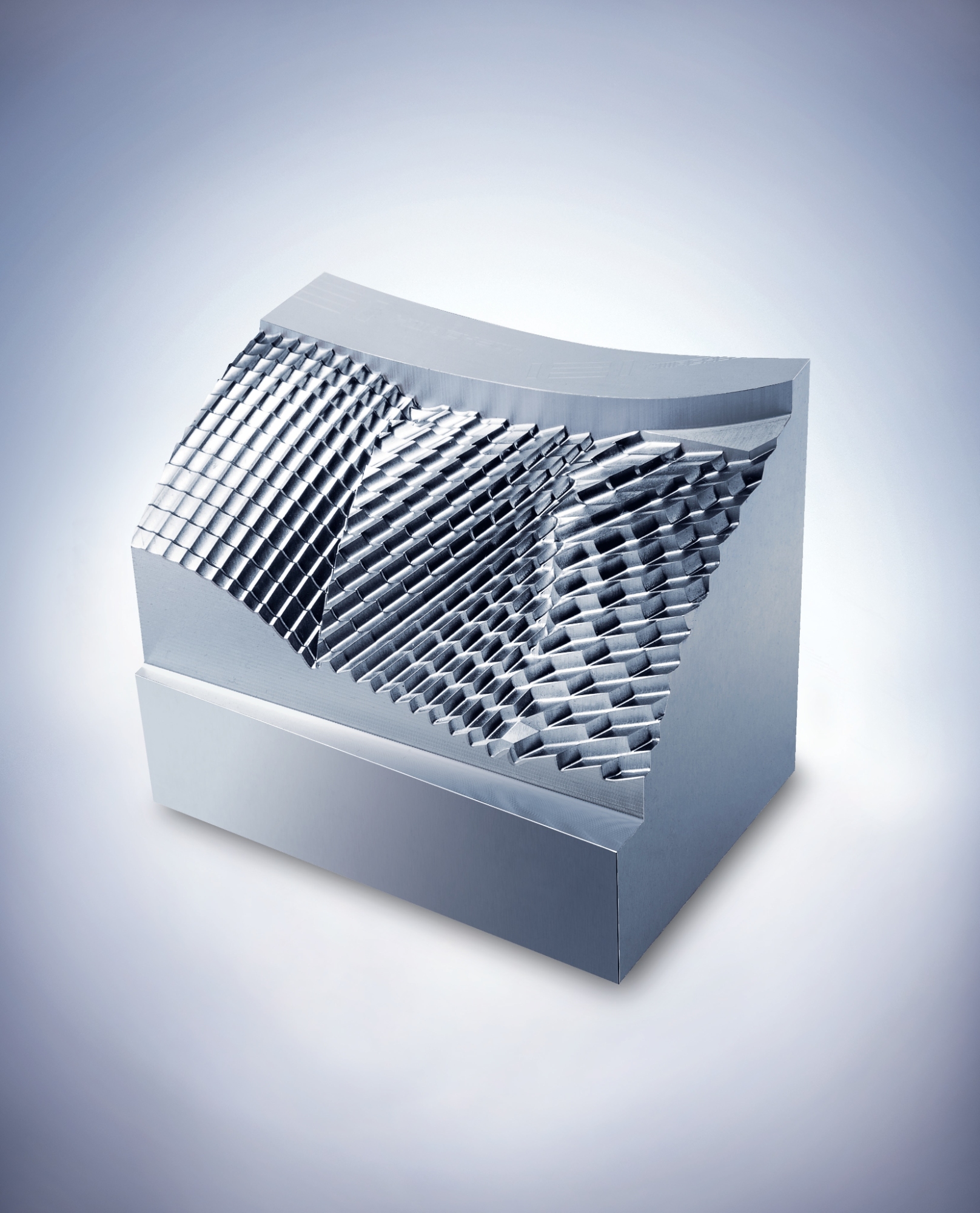

Process Sample

Optical Mold / Automobile / NAK80

Cellular Phone Mold / Mobile / NAK80