Machining Centers

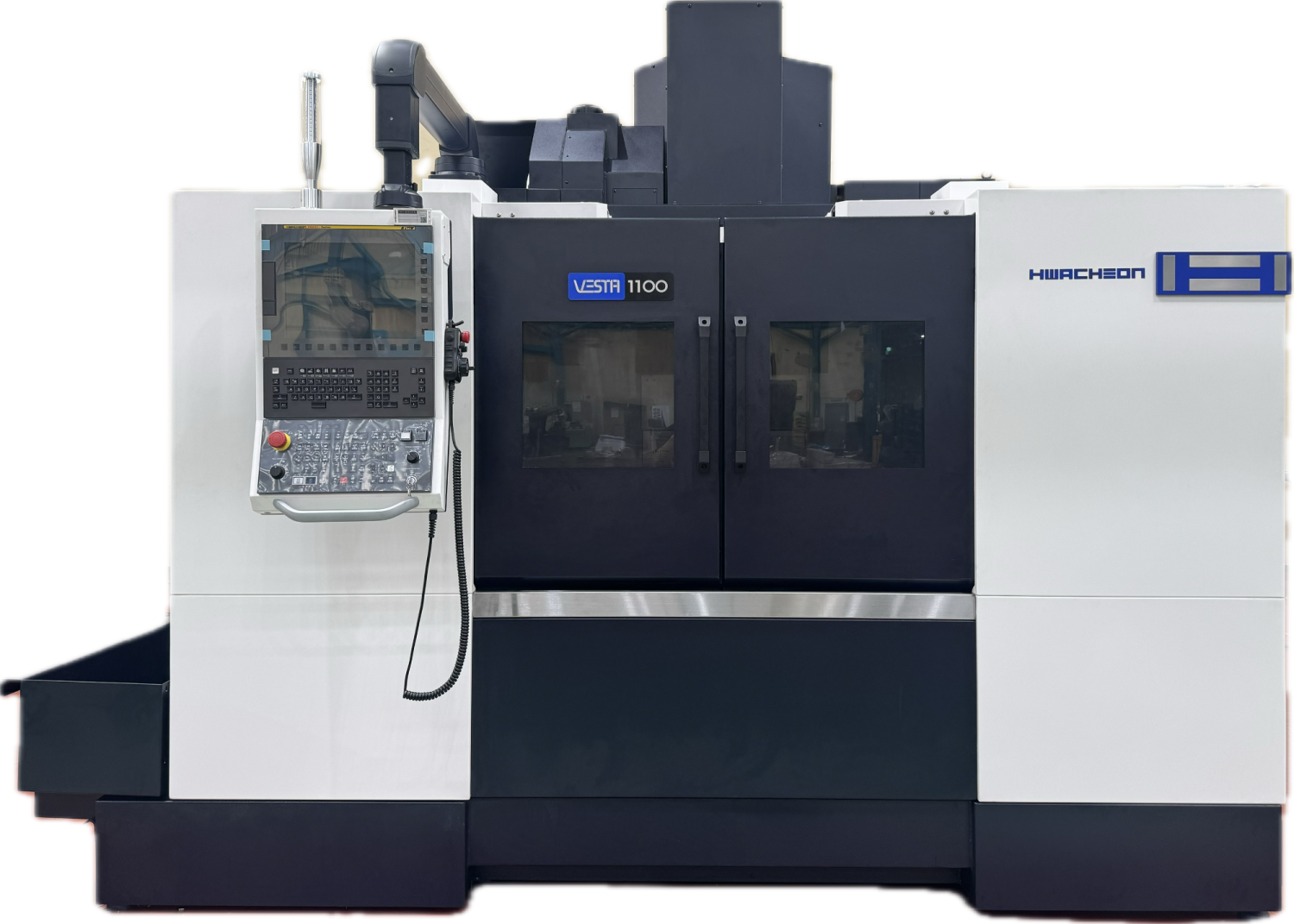

VESTA-1100

Following the success of the VESTA-1000+, Hwacheon proudly introduces the VESTA-1100 – a new-generation vertical machining center designed for companies seeking superior stability, speed, and precision.

Equipped with a high-speed spindle, a rigid, vibration-resistant structure, and intelligent control software, the VESTA-1100 is expected to provide manufacturers with an optimized machining solution that reduces costs, increases productivity, and expands machining capability from small components to large workpieces.

Installation area size has been minimized relative to the size of other tools of the same class for more efficient usage of space in customer’s factory

Enhanced Productivity and Operator Efficiency

High Productivity

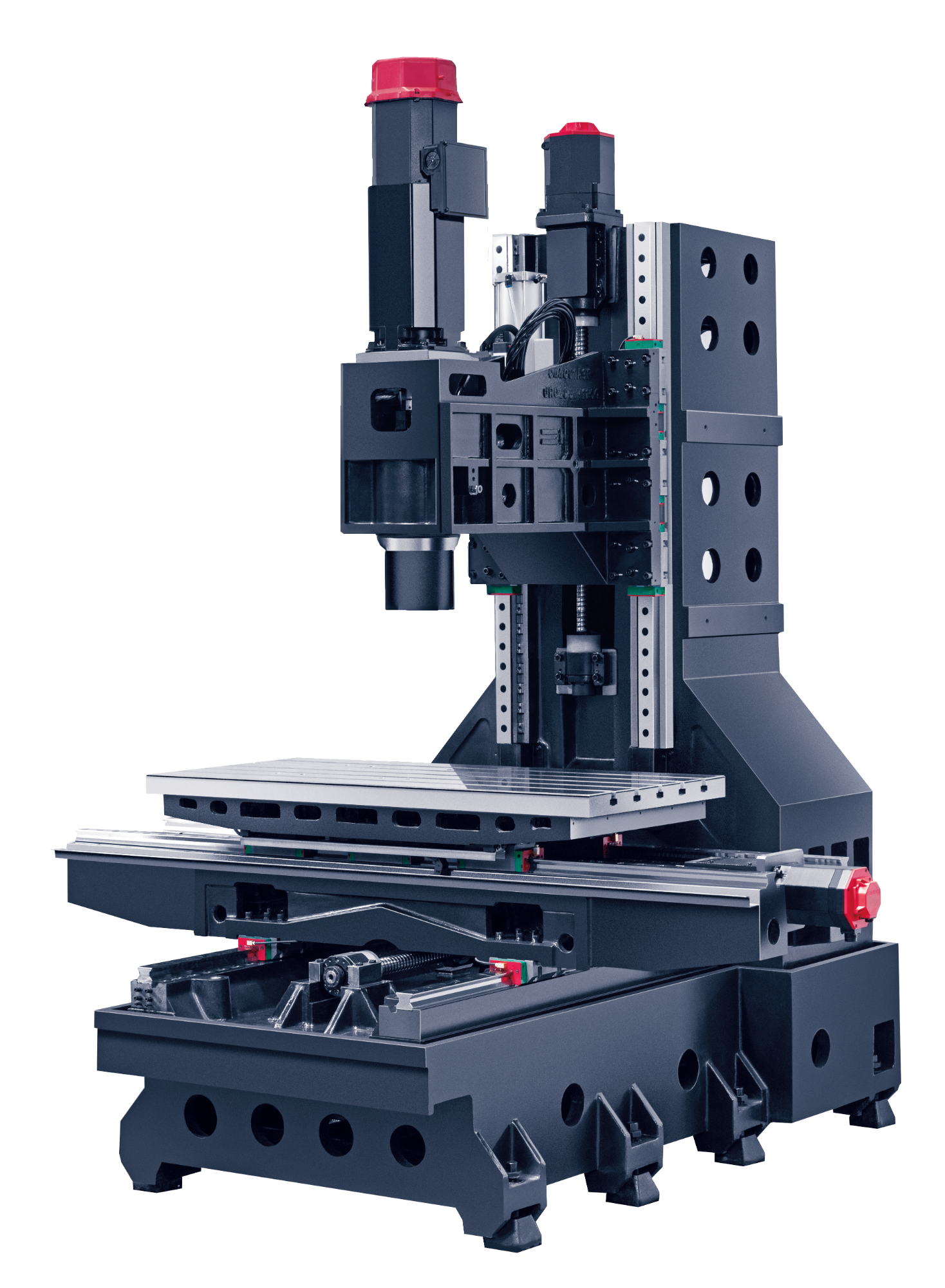

25% Heavier Frame

145% Stronger Rib Structure

210% Increased Rigidity

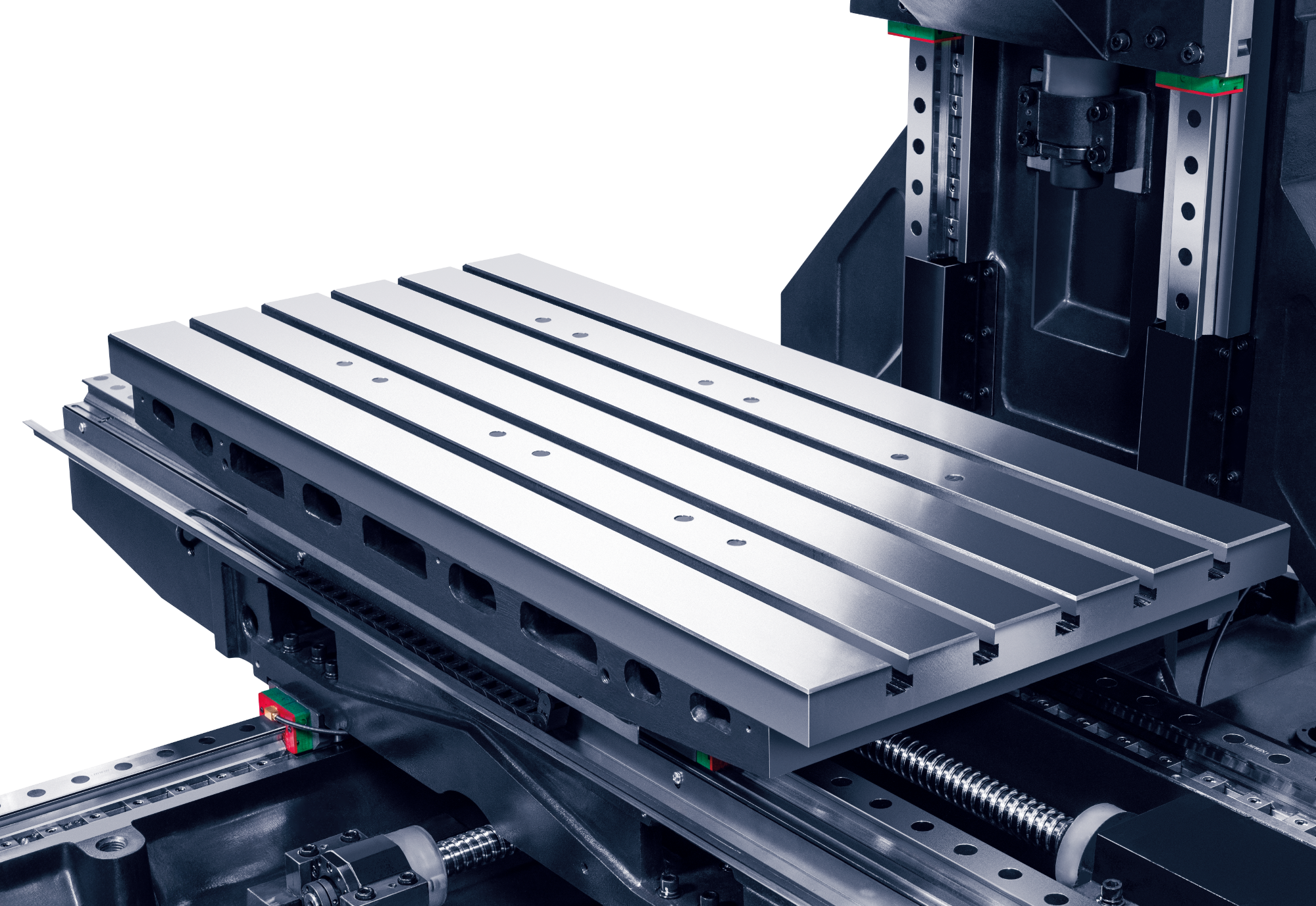

44% Larger Work Area

User Convenience

16% Smaller Installation Area

Chip Conveyor with Side/Rear Discharge

Adjustable Operating Panel

250% larger coolant tank

Smart guide software

Eco-Friendliness

60% Lower Lubrication Costs

24% More Efficient Coolant Pump

50% Less Energy with Inverter-Controlled Chip Conveyor

Up to 26.6% Energy Savings with the Newly Designed UI

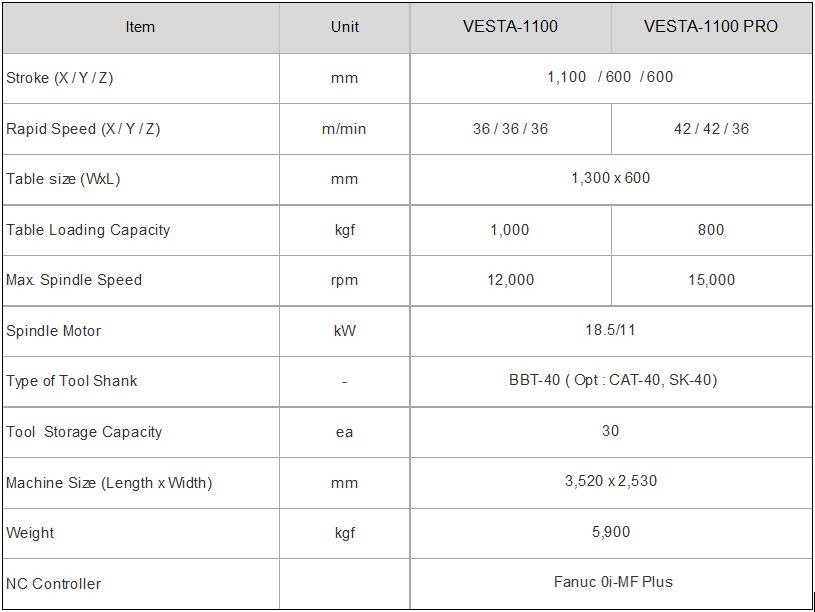

Specifications

Mounting software

Hwacheon Tool Load Detect System

"Detect and diagnose the most minute of tool-end point movement"

HTLD constantly monitors the tool wear to prevent accidents, which may occur from a damaged tool and help to stop tool wear from deteriorating the workpiece.

(The load is measured every 8 msec to ensure accuracy.)

Hwacheon High Efficiency Contour Control System

"Roughing quickly, finishing is precisely"

HECC offers an easy to use programming interface for different workpieces and different processing modes.

The system provides a precise,custom contour control for the selected workpiece, while prolonging the life of the machine and decreasing process time. The customizable display provides real-time monitoring and quick access.

Cutting Feed Optimization System

"Maximize your productivity with intelligent system"

OPTIMA utilizes an adaptive control method to regulate the feed rate in real time, to sustain the cutting load during a machining process. As a result the tools are less prone to damage and the machining time is optimized.

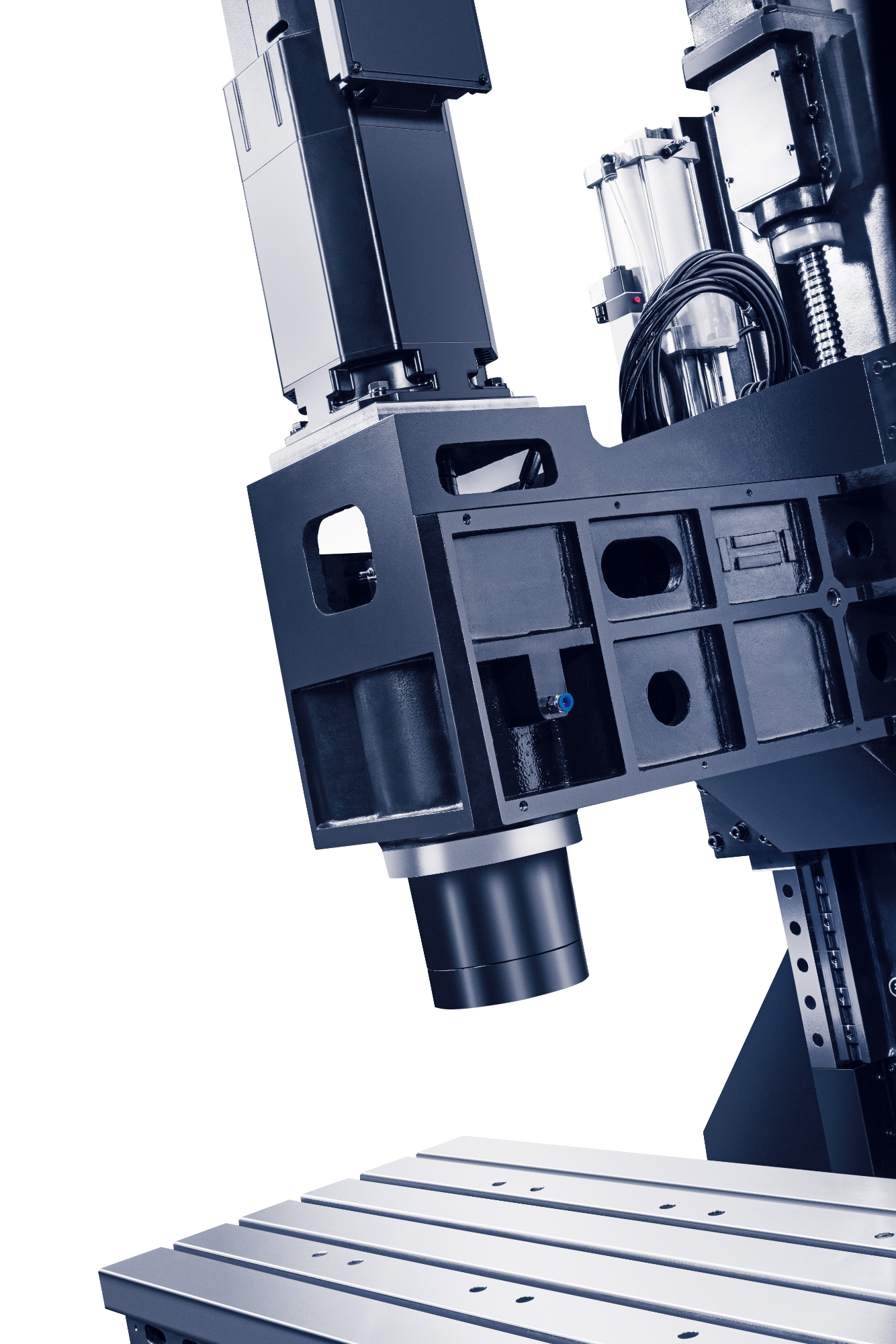

Hwacheon Spindle Displacement Control System

"Real-time correction for the displacement in the spindle"

When the spindle rotates at high speed, the centrifugal force drives the taper to expand, causing errors in Z axis. HSDC constantly monitors the temperature at each spindle region and makes optimal prediction for thermal displacement.

The system then makes necessary adjustments and eff ectively minimizing thermal displacement.

Hwacheon Frame Displacement Control System

“System for maintaining processing accuracy for a long period of machining"

HFDC is equipped with highly sensitive thermal sensors in the casting region where thermal activity is suspected; monitoring and correcting displacement.

Hwacheon Thermal Displacement Control System

"Hwacheon Spindle Displacement Control System

+ Hwacheon Frame Displacement Control System"

HTDC integrates the Hwacheon Spindle Displacement Control system and the Frame Displacement Control System.