LARGE SIZE 5-AXIS MACHINING CENTER SIRIUS-3000 5AX

Ever since we announced the launch of our NEW Large Size 5-Axis Machining Center SIRIUS-3000 5AX, we received a number of enquiries about its benefits. So, we have

gathered some of the top queries and compiled them in this article.

Your Questions About Large Size 5-Axis Machining Center SIRIUS-3000, Answered

#1 How fast

SIRIUS-3000 5AX has the capabilities to machine complex shaped components and multiple processes much faster with the simultaneous 5-axial machining method and the 3+2

or 4+1-axial machining method in a single setting.

It adopts a high speed and high precision universal head with direct drive motors developed by Hwacheon, which facilitates quality product production even under prolonged

machining. The maximum feed and rapid rates for X / Y / Z axes at 60 / 60 / 45 m/min provides high speed machining which improve production efficiency and minimize cutting

time drastically. The faster a machine needs to perform in all axes, the more rigid should be the mechanical structure of the machine.

SIRIUS-3000 5AX is designed and manufactured with a stable gantry machine structure, rigid LM guide for X, Y and Z axis, twin ball screws on Z-Axis and application of glass

scale feedback for all axes. Its NEW drive system comprises of linear motors in X and Y axis. These features offer unparalleled high speed and high precision performance

required in today’s 5-Axis machining.

#2 How precise

SIRIUS-3000 5AX is equipped with a powerful spindle, standard with HSK-A63 tooling system, maximum spindle speed 24,000rpm, 69Kw power and 126Nm torque.

The powerful spindle uses an unique OIL-JET Lubrication System with high quality ceramic bearings. Fresh oil is being temperature-controlled injected onto the bearings and

returned to the chiller unit, filtered and reused again. Creating a stable and constant temperature environment for bearings, resulting in maximum accuracy. The built-in motor

spindle, designed and made in-house by Hwacheon, provides highest precision even during the longest cycle times.

Further improved surface quality (Ra 0.8um) is made possible by 5-axis simultaneous machining with R-type end mill.

The low-cantered machine design further enhances the static stability and accuracy of SIRIUS-3000 5AX. Supported by gantry type structure, they provide best rigidity and

optimum dynamic, vibrations are avoided or kept at a bare minimum. The workpiece weight does not influence the machine dynamic as it is static and not moving.

Additionally, the machining center is integrated with 5-Axis software technology developed by Hwacheon. These functions contribute to high performance in surface quality, all in a

single set up at maximum possible cutting speed and precision, to achieve the necessary tight tolerance and on time production schedules.

#3 How flexible

The large table offers the flexibility to produce mid to large size mold & die and various precision parts.

-

Table size : 3,500mm x 3,000mm

-

T Slot (W x P) : 22mm x 200mm (18ea)

-

Maximum loading capacity : 20,000 kg

Additional flexibility is realized by having its standard-fitted Automatic Tool Changer which enable prompt machining of parts that require many tools.

With a capacity of up to 90 tools, the Automatic Tool Changer eliminates the need to switch tools, providing high productivity when running multiple complex parts.

#4 What are the industry applications?

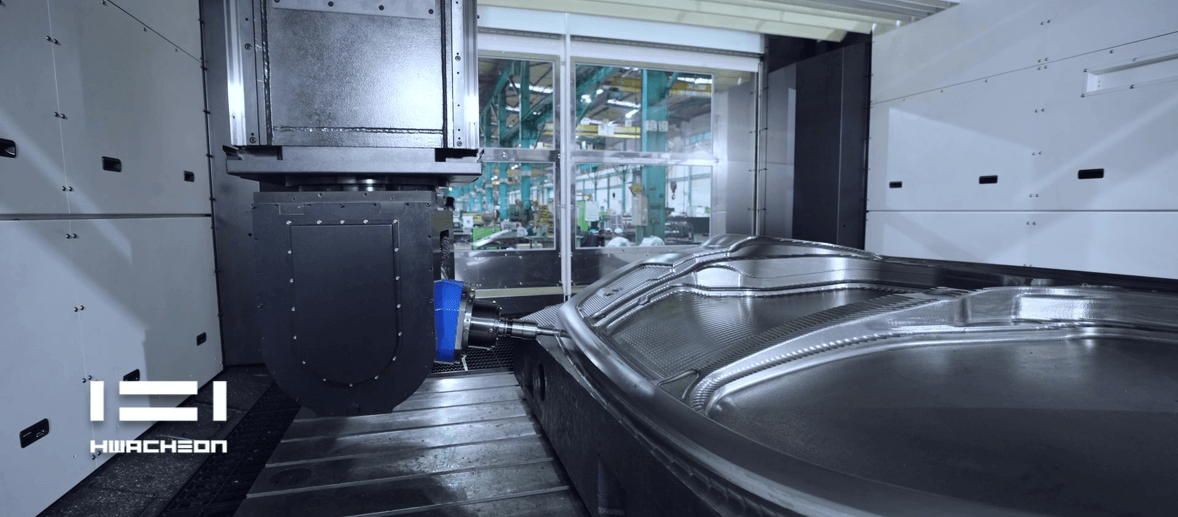

Apart from machining large size precision molds, SIRIUS-3000 5AX is ideal for creating mid to large size complex and contoured parts required in the aerospace, automotive, oil &

gas, energy and components for heavy industries, where precision and intricacy are often the key criteria.

Application Example: Automobile Press Mold

#5 What is the price?

5-Axis Machining Centers are often seen as expensive and high investment. Higher quality 5-Axis Machining Centers may cost more. However, they can achieve extremely high

accuracy and tight tolerances, and increase your business opportunities in the competitive CNC machining market.

Pricing is mainly dependent on the base machine, options and systems selected as well as how and where the machine is manufactured. Like any other products, the term “you

get what you pay for” is highly relevant.

SIRIUS-3000 5AX is designed and manufactured by Hwacheon in South Korea. Built with top-notch quality and precision, extreme durability and through the use of premium raw

materials and top-grade casting technologies. It provides good overall mechanics and are capable to deliver long-term accuracy and stability.

#6 What other useful faetures

The performance of a 5-Axis Machining Center is typically gauged on its speed, precision and flexibility.

The SIRIUS-3000 5AX is an new enhanced version and a big step up from the current proven SIRIUS-2500 5AX, which is known to provide highest performance at very

competitive prices.

SIRIUS-3000 5AX is built with the latest engineering and manufacturing techniques for either high precision large size Mold & Die or to achieve higher accuracy for specific large

parts. The 5-Axis Machining Center is equipped with Hwacheon’s proprietary tech nologies such as precision enhancement software and productivity enhancement software

(HECC, HTLD, HTDC, HRCC and Optima) to ensure optimized machine performance.

Additional features such as machine monitoring and remote diagnostics are also available.

#7 How to bye the right 5-Axis Machining Center

First and foremost, you need to have a clear assessment of the projects you want to take in.

Performing an assessment on the sizes and complexity of parts, materials to be machined, level of precision, cutting tools, floor space, etc allows you to select the most efficient

and cost-effective 5-Axis Machining Center, and the required options and systems.

There are also other important factors to consider. Read more about choosing the right CNC machine tool for your factory here.

It’s time to give SIRIUS-3000 5AX a deeper look.

Watch video to view more features about SIRIUS-3000 5AX.

Alongside trends in large size intricate and complex components, 5-Axis machining is seen as the most practical manufacturing method.

With extensive experience in manufacturing large size CNC machines, Hwacheon has the expertise to custom make Large Size 5-Axis Machining Center according to your

specific needs. You can be assured of high standard of quality through our rigorous testing and be supported by experienced engineers who understand your applications.

Contact us for a discussion, a catalogue or to request for a price estimate.