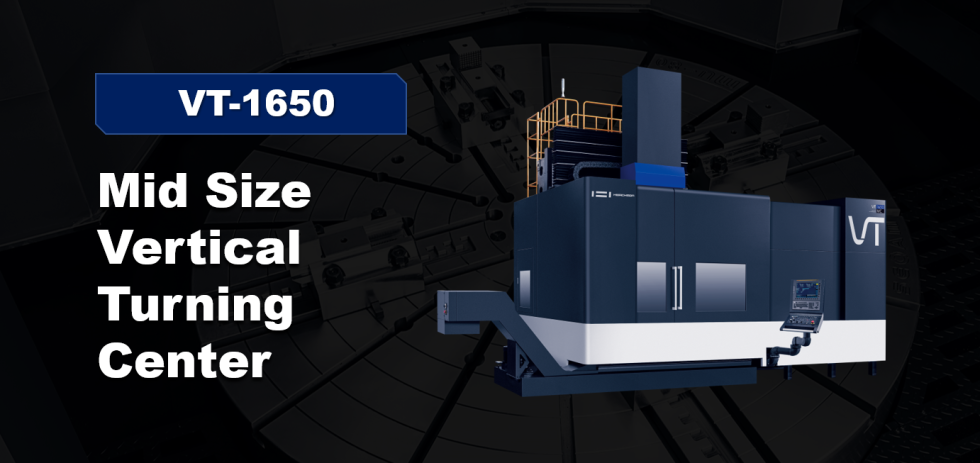

MID SIZE VERTICAL TURNING CENTER VT-1650

Vertical Turning Lathes (VTL) / Vertical Turning Centers are commonly used to make cylindrical components for the manufacturing of machinery and equipment used within aerospace, shipbuilding, wind power & energy, petrochemical, mining industry and many various industries.

Components for machinery and equipment are often large and heavy. Manufacturers require commitments in improving processes and investments in machines, facilities and manpower. The ability to fulfil these variables enable your production to be flexible, adaptable and ahead of competition.

Whether you are machining standard metal or high performance alloy, you need a reliable Vertical Turning Lathe (VTL) / Vertical Turning Center that performs, to meet your requirements on specs, on time and on budget.

Proven Past. Innovative Present. Hwacheon’s newest VTL VT-1650

The term “round parts are just parts” is really not quite true. As a matter of fact – parts are becoming increasingly challenging and complex.

There are unique challenges associated with machining mid to large size round parts:

-

Part is cylindrical and complex

-

Large surface areas

-

Raw materials are heavy

Vertical Turning Lathe (VTL) / Vertical Turning Center VT-1650 with 65” chuck is the latest addition to the proven and trusted VT Series – VT-650 / VT-950+ / VT-1150+ / VT-1650 / VT-2000 / VT-3000 / VT-4500.

VT-1650 features a ‘One Gear Box’ drive system that minimizes thermal deformation, and a low center of gravity design with a one piece base frame, providing stability and load distribution for a highly rigid structure.

Designed to drive performance, VT-1650 is highly accurate for most cutting conditions of mid to large size cylindrical part production or tough material applications. Manufacturers can benefit from its heavy duty structure, powerful spindle and state-of-the-art craftsmanship that assure superior dynamics and accuracy.

A combination of high performance and unique features packed intoone rigid machine, VT-1650 is Made-By-Hwacheon, Made-In-Korea, based on decade long experience of manufacturing machine tool of rigidity and reliability in machining.

Key Features of VT-1650

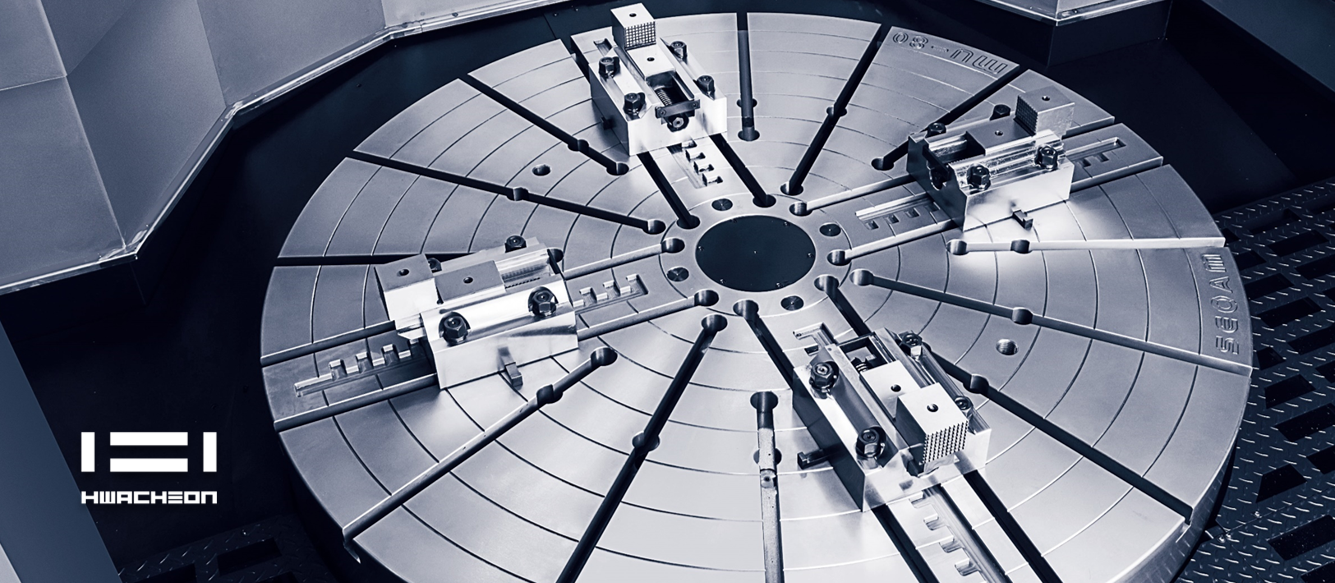

#1 Powerful Table

-

Standard table : 65” manual chuck

-

Table motor : 45 / 37 kW (Max. torque : 27,587 Nm)

-

Ø1,000 mm large Size Bearing (Loaded Weight : 10 tons)

#2 High Rigid Structure

-

New “One Gear Box” design for main spindle drive as well as C-Axis drive system.

-

High stability through low balanced design

-

Box way type high rigid load dispersion structure (X/Z/W-axis)

#3 High Productivity Milling Ram

-

Best ram stroke in its class : 1,000 mm. Ram size: 250 x 250 mm

-

Best milling speed in its class : 3,000 rpm

-

Turning holder 3 type (opt.) + BT-50 milling holder (opt.)

-

Milling motor : 26 / 22 kW (std.)

-

Magazine : 16 ea (std.)

#4 Best W-axis specifications in its class

-

High rigid column structure (W-xis stroke 900 mm)

-

High accuracy position control by using twin servo motor (5.5 kW – 2ea)

-

Heavy duty cutting by W-Axis clamping system

-

Powerful hydraulic break unit (4 sets)

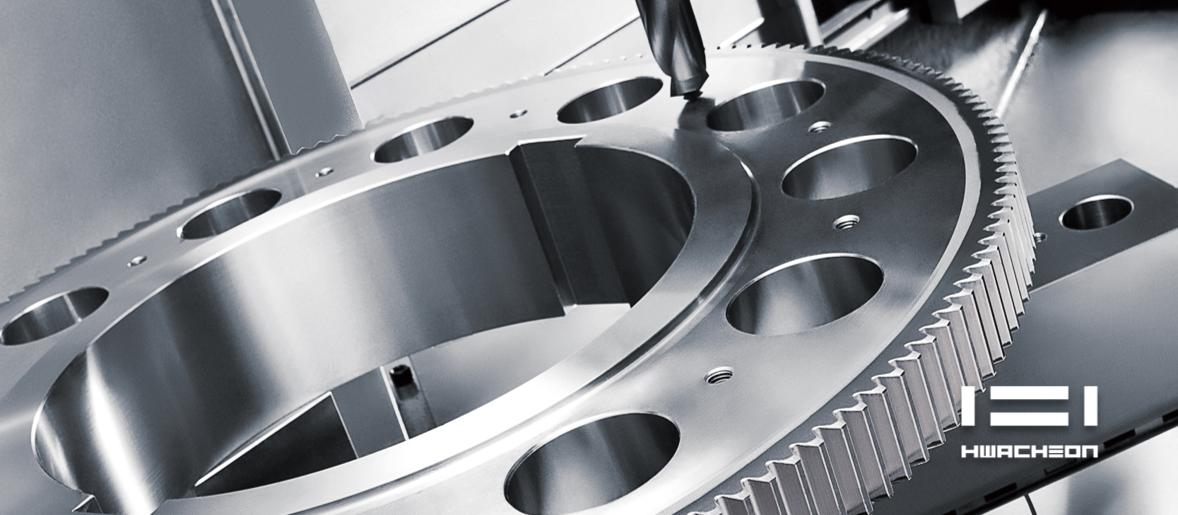

Turn & Mill. Complete Machining.

The high rigid ram offers stable machining even for deep ID processes. VT-1650 is equipped with a milling unit which enables optimize multi-process machining with a single chucking. The milling unit is driven by a powerful AC spindle motor and combined with an accurate C-Axis drive ensures precise table index up to 0.001˚, enabling accurate machining of various operations such as milling, tapping, drilling, grinding, in only one setting.

Why Invest in Hwacheon VTL-1650

The very first VT machine has been installed more than 35 years ago. Today, thousands of VT machines are operating in various industries all over the world.

As the first company in the Korean world of machine tool manufacturing, Hwacheon take great pains to produce high quality machines that are engineered to reduce your total machining costs. The basis for our approach is “Mechanical Stability”.

These include ensuring top-notch quality and precision, extreme durability through use of premium raw materials and top-grade casting technologies, and utmost precision through years of craftsmanship.

Contact us to learn how VTL VT-1650 can improve your productivity, to request for an estimate or to view a machine.