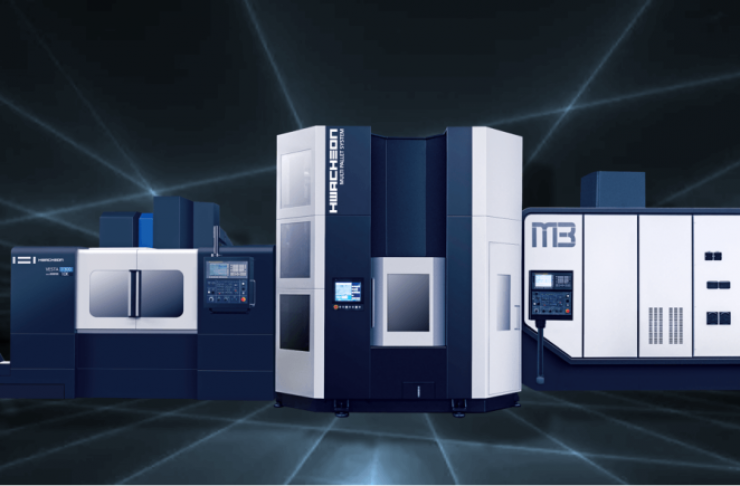

SIMTOS 2024. HWACHEON CNC MACHINE – DESIGNED BY USES. BUILT BY HWACHEON.

We’re Back Again!

This time, presenting a targeted and innovative showcase of CNC machines and solutions tailored for the world’s key industries.

18,000 m² of technology, 16 machines, 5 automation systems, software stations, machining demonstrations and sample displays. Plus, exclusive show specials on CNC Smart Interface, CNC Solutions for Large and Extra-Large Components, and EV Mold & Die Solutions.

NEW Machines

i3

Integrated Multi Axis – Multi Tasking Turn Mill Centre

Multi-functional B-Axis spindle. Large size ATC. Equipped with new “Harmony” Smart Interface. Lower turret and second main spindle are optionally available plus many other options to optimize your machine for your application needs.

AF4

Horizontal Machining Center

High torque spindle with 15,000 rpm. Spindle designed and built by Hwacheon. Optional with 20,000 rpm and Oil-Jet lubrication. Standard with Automatic Pallet Changer. The AF-4 will demonstrate how to optimize machine performance and to reduce non-productive periods.

Best Selling CNC Machines

M1-5AX / D3-5AX

5-Axis Machining Centers

Flexibility, speed, accuracy, and performance optimization.

U1 / SIRIUS-UM+

Vertical Machining Centers

Competitive Mold & Die solutions for EV and semiconductor components.

Hi-TECH 230BL YSMC / CUTEX-180AL YSMC

Multi Axis Turning Centers

High productivity and precision multi axis technology for batch or mass production

Large / Extra Large CNC Machines

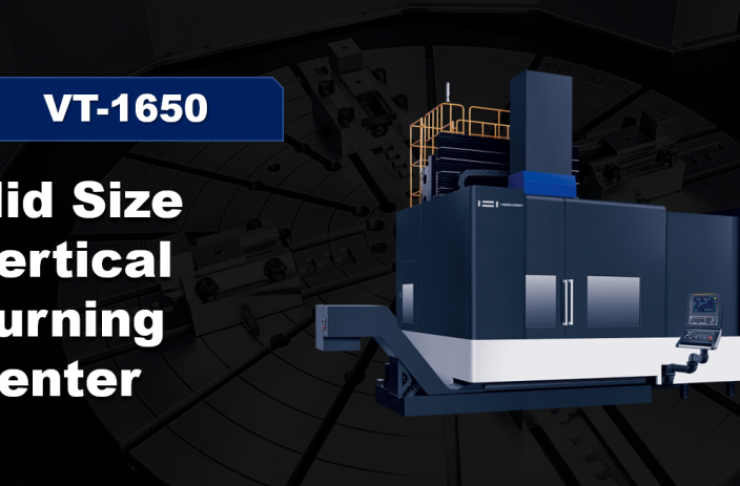

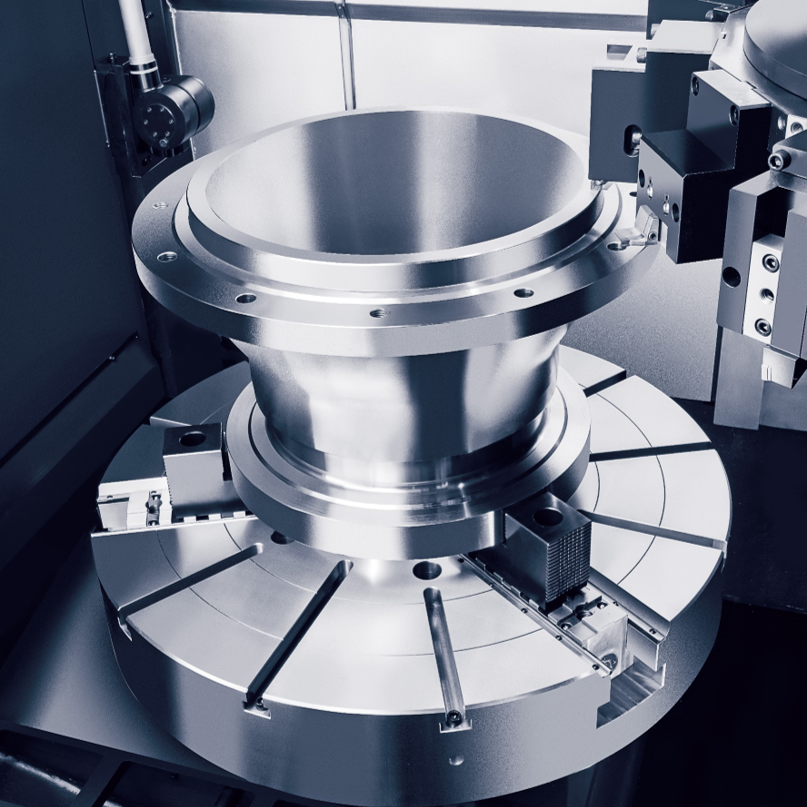

VT-1650

Large Size Vertical Turning Center

Manufacturers of massive cylindrical components can view the large size VTL VT-1650. Ram type with 65” chuck for medium to large size heavy duty workpieces commonly used in ships, wind turbines and many other large industrial components.

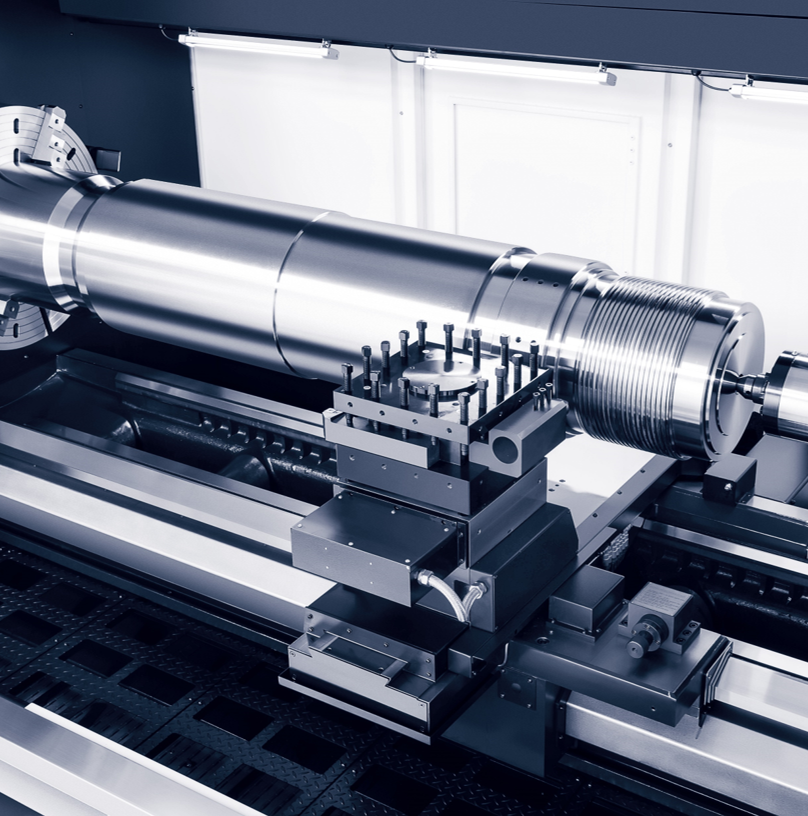

MEGA-110

Heavy Duty CNC Lathe

MEGA-110 features a three-speed transmission spindle which allow high spindle speed as well as powerful low torque. With a machine weight of 17,500 kg, MEGA-110 is well suited for large and heavy parts, pipes, and shafts.

Software Solutions

At the Software Station, attendees can view demonstrations on how CNC software can be used to improve surface quality, accuracy, thermal displacement control, cutting feed optimization, and other advantages.

Beyond productivity software, attendees can view live demonstration on a beneficial yet inexpensive solution to cost-effective savings in your production processes – M-Vision Pro / Plus – Real Time Machine Status Monitoring Software.

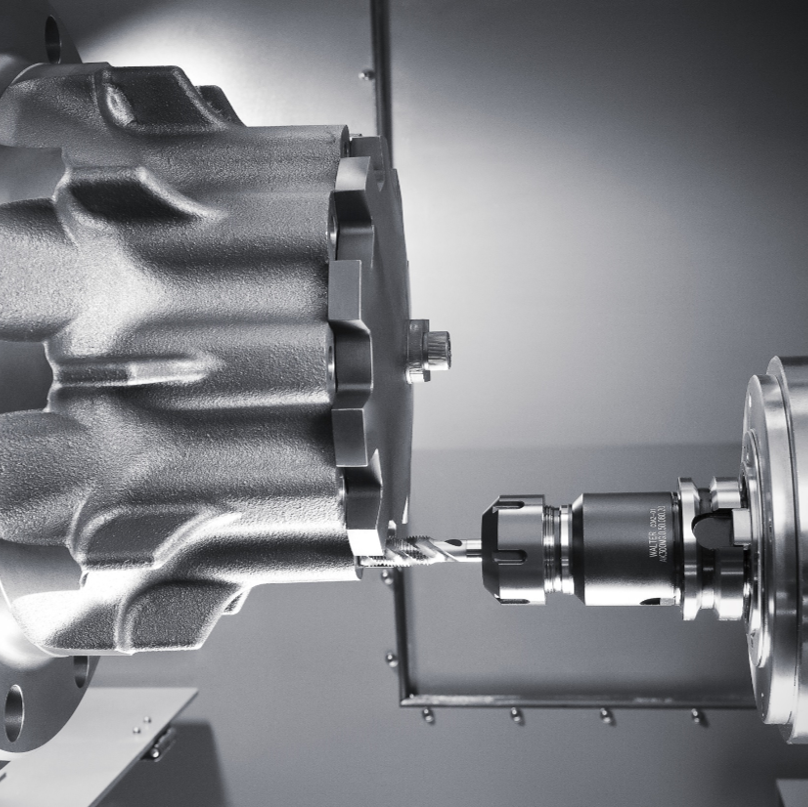

Whether your interest is in machining of intricate parts, complex parts, long cylindrical parts, parts which require many various and different operations, or managing extra-large projects, we have an exacting solution for you.

We look forward to welcome you at HWACHEON booth.

In case you are unable to visit our booth and are keen to know more about any of the showcased machines, please feel free to contact us for a discussion or for more information.